|

|

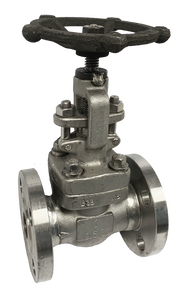

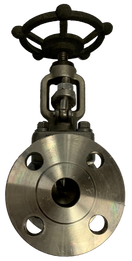

Globe valves are valves types used to regulate, start, or stop fluid flow in systems. Globe valves are made following the API 602 and ASME B16.34 standards. Globe valves are low pressure valves used in many applications and industries. The valve is designed with a movable disc joined to the valve stem which allows for easy regulation of fluid flow in systems. Globe valves are available in sizes ranging from 3/4” to 6” and can work with pressure ranging from 150# to 800#. Globe valves are made from materials such as cast iron, cast steel, forge steel A105 and stainless steel SS316. The connection types for globe valves are welded end socket weld, 150# flange end, threaded end (BSPP and NPT), and JIS 10K flange end. |

Material Specification |

|

Connection Type |

|

Size |

|

Working Pressure |

|

Globe Valves Specifications

To learn more about individual product specification, please read the details below:

1. What are Globe Valves?

Globe valves are made following API 602 and ASME B16.34 standards and are classified as the most renowned valves available. Globe valves as linear motion valves can control, shut down, or open a system's fluid flow. The globe valve has an outside structure resembling a globe, hence, the name it’s called.

Globe valves are designed with a disc that moves perpendicular to the flat surface of the valve seat. This angular contact between the disc and valve seat gives an improved sealing and reduces susceptibility to leakages. When the valve is at an opened position, process fluid flows through a middle seat hole. However, the valve reduces the flow rate by changing the gap between the movable disc and seat.

Regular valves or globe valves have been designed before modern times and they are applied in throttling and isolation systems. The globe valves have their body halves structured in a spherical shape and divided by an inner baffle. Today, many globe valves have been restructured to other shape asides from the conventional valves' spherical shape.

The disc in globe valves is produced in different types. These types are shown in the table below:

Globe valves are designed with a disc that moves perpendicular to the flat surface of the valve seat. This angular contact between the disc and valve seat gives an improved sealing and reduces susceptibility to leakages. When the valve is at an opened position, process fluid flows through a middle seat hole. However, the valve reduces the flow rate by changing the gap between the movable disc and seat.

Regular valves or globe valves have been designed before modern times and they are applied in throttling and isolation systems. The globe valves have their body halves structured in a spherical shape and divided by an inner baffle. Today, many globe valves have been restructured to other shape asides from the conventional valves' spherical shape.

The disc in globe valves is produced in different types. These types are shown in the table below:

Needle Type |

|

Ball Types |

|

Composition Type |

|

2. How does a Globe Valve operate?

Like other valves, the globe valve body is inscribed with a flow direction arrow to guide and indicate the inlet and outlet ports. The fluid flow in the globe valves is unidirectional and connected with the inlet or pressure side placed under the valve seat. The globe valve has many major components which are discussed below:

|

For balanced plugs, they are simpler to close due to the holes designed on the plug. A leak passage may occur between the cage and plug.

- Stem: the stem is a connecting device from the handwheel handle to the valve's inner part. They can be used for manual threaded valves or valves controlled with actuators. The smooth stems are encompassed with packing material to avoid fluid leakage. This material is prone to wear and can be easily changed during maintenance of the valve. The smooth stem gives the threaded ends the allowance to connect to the handwheel plug.

- Seat: the seat ring gives a uniform, replaceable, and stable shut-off area, and it is connected by screwing in or torque.

3. How does a Glove Valve work?

|

There are several design types for the globe valve body. However, the most popular types are the angle type, Z-type, and Y-type.

|

4. Where is a Globe Valve used for?

|

The globe valve is used in a variety of applications such as:

The benefits of applying globe valves in system installation include:

|

GLOBE VALVES CATALOGUE