|

|

|

Material Specification |

|

Connection Type |

|

Size |

|

Working Pressure |

|

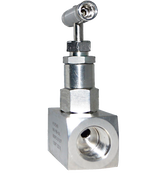

Needle valves are also known as plunger valves or flow control valves. They are designed to serve as a tool for the accurate control of flows in systems. They are made from either stainless steel or carbon steel and these two materials are applied in different industries.

The valve has a working pressure between 6000 PSI and 10000 PSI. Also, they are produced in different sizes ranging from 1/4” to 1”. For the valve connection, the National Pipe Thread (NPT) and British Standard Pipe Parallel (BSPP) ends are used. They are designed in a needle-like shape, hence the name. Needle valves can also be used as shut-off valves, however, they are mostly used for systems with low flow rates.

The valve has a working pressure between 6000 PSI and 10000 PSI. Also, they are produced in different sizes ranging from 1/4” to 1”. For the valve connection, the National Pipe Thread (NPT) and British Standard Pipe Parallel (BSPP) ends are used. They are designed in a needle-like shape, hence the name. Needle valves can also be used as shut-off valves, however, they are mostly used for systems with low flow rates.

1. What is the difference between a Needle Valve and a flow control valve?

|

Needle valves are valves used to safely secure the flow fluids in low flow rates systems and its control flow in two directions, while flow control valve flows in one direction only. Valves are devices fitted into pipes or hydraulic systems used for the regulation and controlling the passage of fluids. These fluids may be gaseous, fluidized solids or liquids. There are various types of valves which include needle valves.

They are used to control the flow of fluids in hydraulic systems. Fragile gauges are sometimes affected by sudden pressure surges from gases and liquids flowing in the system. However, a needle valve serves as a protector for these gauges when installed in the system. Generally, they are majorly used in low-pressure systems, however, if the valve material can withstand higher pressures, needle valves can be used. |

Needle valves can be made from stainless steel, metal alloys, brass, or bronze, however, the common materials are carbon steel and stainless steel SS316. Most needle valves are manually operated, however, automatically operated needle valves can be available upon request.

Needle valves are applied in different areas where pressure regulation is needed. The standard working pressure of the needle valve ranges from 6000 PSI to 10000 PSI and this value changes according to the temperature level. An increase in the temperature level of a needle valve causes a decrease in the working pressure. At the same time, a decrease in temperature causes an increase in working pressure.

Needle valves are applied in different areas where pressure regulation is needed. The standard working pressure of the needle valve ranges from 6000 PSI to 10000 PSI and this value changes according to the temperature level. An increase in the temperature level of a needle valve causes a decrease in the working pressure. At the same time, a decrease in temperature causes an increase in working pressure.

2. How does a hydraulic Needle Valve work?

|

Needle valves are very beneficial devices due to the following reasons:

|

3. How does a Needle Valve work?

A needle valve has three major components – the stem and stem tip, valve body and seat, and the bonnet and packing. The needle valve is designed in a compact way that allows the body to produce directly from square or hexagon bar stock. Here’s an insight into the components parts of the needle valve:

The stem tip is either short or long and tapered, this is designed based on the application intended for the needle valve. The tapered stem tip seat is in line with the needle taper and is used for regulatory applications. Short stem tips prevent leakage in small orifice valves while blunt stem tips enable the full flow of fluids. Stem tips are mostly made from metal materials due to their durability.

- The stem and stem tip: the stem has a feature that allows micrometer-like adjustment of the needle. Also, a scale can be incorporated into the stem to allow precise resetting of the flow rate of the fluids. The vibration of the valve can lead to a change in its configuration, thus, a locking device such as screws, nuts, etc are attached to the internal part of the valve.

The stem tip is either short or long and tapered, this is designed based on the application intended for the needle valve. The tapered stem tip seat is in line with the needle taper and is used for regulatory applications. Short stem tips prevent leakage in small orifice valves while blunt stem tips enable the full flow of fluids. Stem tips are mostly made from metal materials due to their durability.

- Bonnet and Packing: Graphite, O-rings, and Polytetrafluoroethylene (PFT) are common materials used for packing. The bonnet is also packed to prevent leakage during the rotation of the stem and gland nuts can regulate the pressure. The bonnet can be attached as a substantial part to the body, also, it can exist as a separate entity entirely which is joined to the body with nuts.

- Valve body and seat: the valve body of the needle valve is often configured into the L and Z-shaped flow patterns. These are often termed as angle or globe patterns.

4. What is a Needle Valve used for?

|

Needle valves are used for the following:

Primarily, needle valves are regulators and their peculiar model makes it easy to control the level of fluid passing through the valve. |

5. What are the selection requirements for Needle Valves?

|

While selecting needle valves, you have to consider the following requirements:

These four requirements are major factors that would determine the effectiveness of the needle valve. Also, any mistake on these factors can lead to damage to the system or proneness to hazard for users while working. |