Let's learn more about Both-Well

Both-well Company was founded in 1985 and it’s situated in Ren-Wu District, Kaohsiung. Both-well Company specializes in the production and distribution of high pressure forged fittings used in hydraulic systems and pipeline installations to the global market. The company’s brand name signifies the conscious efforts of individuals in attaining a win-win outcome amongst clients and both-well personnel which contents both sides.

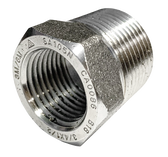

Our company is a distributor of Both-Well products. The products of Both-Well Company are majorly made of Stainless steel SS316 and Steel A105 materials. More so, the working pressure ranges of products have a minimum of 2000# and a maximum of 9000# depending on the specifications of the product.

Our company is a distributor of Both-Well products. The products of Both-Well Company are majorly made of Stainless steel SS316 and Steel A105 materials. More so, the working pressure ranges of products have a minimum of 2000# and a maximum of 9000# depending on the specifications of the product.

1. What is history of Both-Well Company?

Both-Well is a company situated in Ren-Wu District, Kaohsiung established in 1985. By the year 1997, the company had opened a forging factory at Daliao District, Kaohsiung Taiwan. An expansion of the factory to the Ren-Wu factory Kaohsiung occurred in 2000, 2004, and 2009 respectively. The company has a great interest in producing fittings in line with the new technological trends in the world which will lead to quality products being manufactured. The guiding philosophy of the company is to satisfy clients with the best quality products at the most reasonable and competitive price in the market in addition to the prompt delivery of goods ordered.

The effective service performance of the company can be linked to the number of experts in the company alongside partnerships with reputable names for a long period. The main aim of the company is continuous growth and improvement of product quality. Factually, Both-Well is the most reliable manufacturer and distributor of forged fittings in the industrial market today.

The effective service performance of the company can be linked to the number of experts in the company alongside partnerships with reputable names for a long period. The main aim of the company is continuous growth and improvement of product quality. Factually, Both-Well is the most reliable manufacturer and distributor of forged fittings in the industrial market today.

2. What are the production processes employed by Both-Well Industry?

The quality management system of the company runs according to the ISO 9001:2015 standard and PED. The table below shows the Both-Well forged fittings production processes:

Process |

Forging |

Machining - Socket Weld |

Machining - Threaded |

1 |

Round Bar |

Rough Forging |

Rough Forging |

2 |

Cutting |

Drilling |

Drilling Facing |

3 |

Heating |

Facing |

Boring |

4 |

Forging |

Boring |

Threading |

5 |

Chamfering |

Dimensional Check |

Dimensional Check |

6 |

Heat Treatment |

Marking |

Marking |

7 |

Surface Treatment |

Cleaning |

Cleaning |

8 |

Rough Forging |

Surface Treatment |

Surface Treatment |

9 |

- |

Final Inspection |

Final Inspection |

10 |

- |

Finished |

Finished |

Despite being situated in Taiwan, the Both-Well Company still maintains a relationship with the global market in the world. Both-Well products are supplied in various countries such as Canada, Brazil, the United States of America, Australia, Japan, the Middle East, Japan, Chile, the United Kingdom, France, Singapore, Indonesia, Malaysia, Egypt, and many more.

3. Is Both-Well certified?

Both-Well was established in 1985 and became certified with ISO 9001 in 1993. Also, other international standards such as ARAMCO in February 2008 and PED. The Both-Well name is featured alongside other competitors in the approval vendor catalog of well-known petrochemical industries and refineries around the world. Further, Both-Well is the manufacturer specializing in the production of hydraulic system components that got certified by the Japanese quality association with JIS marking (JIS B2316).

The list of end user’s approval given to the Both-Well company are listed below:

The list of end user’s approval given to the Both-Well company are listed below:

- Qatar petroleum preferred vendor list

- Petrobras – Petroleo Brasilero S.A. approved vendor

- Canada COMCO approved vendor

- SABIC – Saudi Basic Industries Corporation approved vendor

- Petronas list of licensed approved vendor

- Exxon Mobil piping accepted manufacturer’s list

- Petronas list of licensed approved vendor

- OXY – Occidental of Oman, Inc. approved vendor

4. What are Forged Pipe Fittings?

The main product manufactured by the Both-Well Company is forged pipe fittings and they are applied in high pressure systems. The main materials used in the production of forged pipe fittings are stainless steel and forged carbon steel. These products are made following the ASME BS3799 and B16.11 standards. The raw material size range is between 19 to 120 mm round bars.

Forged pipe fittings are available in sizes ranging from 1/8” (DN 8) to 4” (DN 100). The working pressure of the forged pipe fittings is 3000 PSI or 6000 PSI. However, higher working pressure of 9000 PSI can be designed based on request. All fittings are inscribed with the material grade, pressure ratings, sizes, heat number, and dimension specification.

To get the catalog list for Both-Well products, please refer to this link.

Forged pipe fittings are available in sizes ranging from 1/8” (DN 8) to 4” (DN 100). The working pressure of the forged pipe fittings is 3000 PSI or 6000 PSI. However, higher working pressure of 9000 PSI can be designed based on request. All fittings are inscribed with the material grade, pressure ratings, sizes, heat number, and dimension specification.

To get the catalog list for Both-Well products, please refer to this link.