|

|

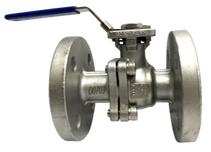

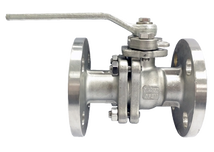

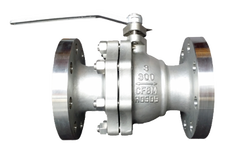

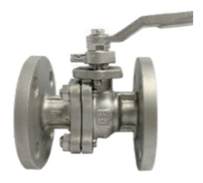

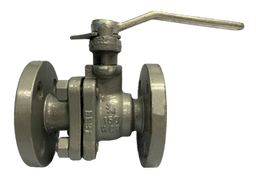

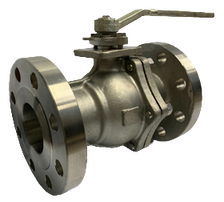

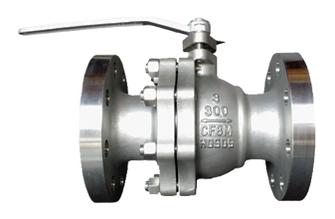

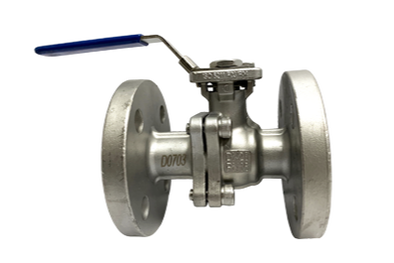

Flange end ball valves are also referred to as Two-piece full bore ball valves. Flanged end ball valves are used in pipelines for shutoff purposes. The valve is ball-shaped with a quarter-turn design. It is designed following the ANSI B16.34 standards and tested according to the API 598 standards. The flanged end ball valves are made from cast steel and stainless steel materials. The sizes available are between 1/2” to 6” and this makes the ball valve fit into different systems and industries. Flange end ball valves can withstand a maximum working pressure of 10kg/cm². The connection types designed for flanged end ball valves are ANSI 150#, PN10/16, and JIS 10K. Flange end ball valves are applied in a variety of industries due to its tight and leak-free sealing of fluids. |

Material Specification |

|

Connection Type |

|

Size |

|

Working Pressure |

|

Flange End Ball Valves Specifications

To learn more about individual product specification, please read the details below:

1. What are Flange End Ball Valves?

Flange End ball valves are classified using various criteria as discussed below:

- Valve Seat Model: soft or metal Teflon

- Valve Bore Size: full or reduced bore

- Ball access: side entry or top entry

- Valve Design: trunnion or floating mounted

- Amount of Ports: the standard 2 ports design model (1 outlet and 1 inlet)

- Body Assembly: 1 piece, 2 piece, or 3 piece

2. What is a fire safe Flange End Ball Valve design?

The fire safe ball valve design is used for valves to maintain their pressure level during or after a fire accident. This design allows the valve to keep a strategic distance from flammable fluids like petrochemicals, gases, and harmful chemicals. When working or trying to create a connection for transportation of ignitable fluids and chemicals, it could be risky, and fire could break out at any point, however, these valves will keep the exposure and accident rate minimal.

Here are some of the unique features and benefits of using fire safe ball valves:

Before a valve is classified as fire safety, the TϋV SϋD carries out a test to check the fire environment's resistance and leakage level. During this test, the valves are exposed to operating under 75% of the water systems' maximum working pressure. It should stand for 30 minutes under the temperature (fire) ranging from 750⁰C to 1000⁰C.

After that, the valve is left to cool down for 10 minutes below a 100⁰C temperature. The testing period also involves the leakage tests from the valve seat to the environment. These tests are strictly conducted, and valves are expected to work a full and close cycle after completing the test.

There are different levels while fire testing the valve, and they are:

Here are some of the unique features and benefits of using fire safe ball valves:

- Designed with a blowout proof system

- Fire safe valve seat

- Incorporated anti-static features

- Made following the API 607 standards

- Dual body sealing to prevent friction between body joints and pipelines.

- Elastomer O-ring seal, which retains the stem alignment, stem seal performance, and minimize packing side-loading.

Before a valve is classified as fire safety, the TϋV SϋD carries out a test to check the fire environment's resistance and leakage level. During this test, the valves are exposed to operating under 75% of the water systems' maximum working pressure. It should stand for 30 minutes under the temperature (fire) ranging from 750⁰C to 1000⁰C.

After that, the valve is left to cool down for 10 minutes below a 100⁰C temperature. The testing period also involves the leakage tests from the valve seat to the environment. These tests are strictly conducted, and valves are expected to work a full and close cycle after completing the test.

There are different levels while fire testing the valve, and they are:

- Fire safe certified and approved: valve with this appellation has successfully passed the tests conducted by external examiners using the standards API 607, API 6 FA, and ISO 10497

- Fire safe by design: the valve under this classification has been designed using the fire safe standards, however, it is on the waiting list for test conduction.

- Fire safe tested: valves with this classification are designed using the fire safe standards, may have undergone the tests, however, they are yet to be certified by the controlling body.

3. What is the difference between ASME, ANSI and JIS Flange End Ball Valve?

|

Flange end ball valves are mostly used in hydraulic systems. These valves are produced using three different connection standards. Each is distinct and isn’t compatible during installation. These standards are:

The size can be read using the National Pipe Thread (NPS), followed by a dimensionless digit, the measure for nominal value size. The NPS is similar to nominal diameter (DN), mostly used by international standards. However, an NPS size greater than 4” is linked to DN 25 (NPS). The table below shows the relation of figures between the NPS and DN:

|

|

4. What is the difference between trunnion and floating ball valve?

|

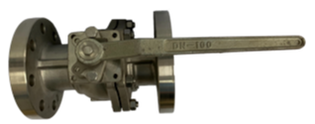

The flange end ball valve is designed using a floating valve structure. The ball is held in the passage of fluid and kept in place by the two elastomeric seat compressions. A shaft is placed on the ball, and this gives the room for a quarter 90-degree turn for easy opening and closing the valve. Simultaneously, trunnion ball valves have a fixed permanent ball to the seats that can move slightly. Trunnion valves work with the upstream flow while floating valves work with the downstream flow.

During the shaft floating valve movement, a load is introduced to the ball, which gets pushed against the valve seats. The floating technique used is cost-effective and light-weighted. More so, it can accommodate a 10” bore size. However, when the size exceeds this, it affects the system's functionality as a result of the heavyweight load on the ball. |

When the ball operates under normal pressure, the floating ball moves against the lower stream seat. An upper stem is produced with the floating valve, which ensures the ball has light displacement. The flange end ball valve can be used with low and medium pressure systems.

5. What are the advantages of Flange End Ball Valves?

|

Flange end ball valves are advantageous because of the following reasons:

The working pressure and temperature measurement for the flange end ball valves are calculated using shell materials and major sealing materials. These sealing materials may be made from rubber or high molecule materials. However, there may be limitations to the selection due to factors like working pressure and temperature, service, the velocity of the fluid, and valves' operational differences in valves. |