|

|

|

Material Specification |

|

Connection Type |

|

Size |

|

Working Pressure |

|

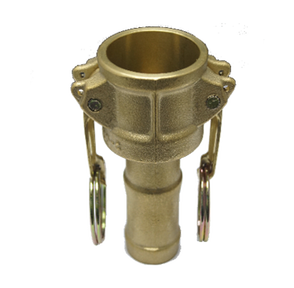

Camlock fittings are made following the EN 14420-7 (DIN 2828) standards. They are also referred to as Camlock couplings, Cam and Groove Fittings, and Ever-tite. The Camlock fittings are widely used in several industries, mainly for hose-to-pipe or hose-to-hose connections. For usability and safety purposes, Camlock fittings are often recommended for liquids transfer, not suitable for steam or gas applications.

Camlock fittings are made from four materials, Aluminum, Brass, Steel, and Stainless Steel. They are also able to withstand a maximum working pressure of 250 PSI. The standard sizes for Camlock fittings range from 1/2” to 4” and they are connected using the Hose Shank or Threaded (BSPT/NPT) types. These fittings are very easy to use and install.

Camlock fittings are made from four materials, Aluminum, Brass, Steel, and Stainless Steel. They are also able to withstand a maximum working pressure of 250 PSI. The standard sizes for Camlock fittings range from 1/2” to 4” and they are connected using the Hose Shank or Threaded (BSPT/NPT) types. These fittings are very easy to use and install.

|

|

STUDY CATALOGUE HERE |

|

1. What is Camlock Fitting?

|

Camlock fittings are low pressure fittings made following the EN14420-7 standards. This standard has a material type, design, marking, and dimensions specifications for each fitting, flange or valves produced. The EN14420-7 is a European standard for connecting hoses, pipes and transfer liquids from one system to another. This is popularly classified as Camlocking Couplings.

Often, MIL-C-27487 (American military) standards are interchanged with the EN14420, however, there’s a difference in part number, hose tail design, and thread type. Camlock fittings are used for the connection of hoses or pipes together. They are applied in different industries such as the pharmaceutical industry, agricultural industry, steel, chemistry, etc. they are also referred to as cam and groove fittings or couplings and ever-tite. They are also used for disconnect pipes and serve as extensive applications as well. |

2. How does Camlock Fitting work?

|

The complete Camlock fittings set contain the following accessories:

Selecting the right Camlock fitting for your system is necessary. To do this, a list of details should be known. They are:

|

To calculate the total working temperature for the fitting, the O-ring material is needed. O-ring materials are assessable as shown in the table below:

|

NBR (Buna N)

The NBR is the customary metal camlock coupling material used for sealing. This synthetic rubber material has a high level of chemical, temperature, hydraulic oil and fluid fats, grease, water, vegetable oil, and air.

EPDM

This O-ring material is used for our polypropylene camlock coupling. It is not recommended for use in areas with grease, aromatic hydrocarbons, and oils, but has a great resistance for substances like alcohol, heat, alkalis, steam acid, and ozone.

The NBR is the customary metal camlock coupling material used for sealing. This synthetic rubber material has a high level of chemical, temperature, hydraulic oil and fluid fats, grease, water, vegetable oil, and air.

EPDM

This O-ring material is used for our polypropylene camlock coupling. It is not recommended for use in areas with grease, aromatic hydrocarbons, and oils, but has a great resistance for substances like alcohol, heat, alkalis, steam acid, and ozone.

|

Viton

This material is not recommended for applications involving amines, steam, low temperature, or esters. Notwithstanding, it has a high resistance level for greases, petrol, silicon oils, aromatic, mineral oils, and many others. Also, it can withstand temperature, weather, and gas fluctuations. PTFE (Teflon) The Teflon material uses rubber filler essentials and is resistant to most chemicals that may be contacted during operation. Further, it has a good temperature temperament, however, the flow capacity is limited. |

3. Are all Camlock Fittings the same?

Camlock fittings are produced in many types, from type A to Type F. These types however have diverse connection types. They are shown in the table below:

|

4. How do you measure a Camlock Fitting?

The maximum working pressure for camlock fittings is 250 PSI. However, some factors define the working pressure. One of these is the body material which is shown in the table below:

Sizes (Inch) |

1/2” |

3/4" |

1" |

1 1/2" |

2" |

2 1/2" |

3" |

4" |

Sizes (DN) |

15 |

20 |

25 |

40 |

50 |

65 |

80 |

100 |

Brass / Aluminum |

150 |

250 |

250 |

250 |

250 |

150 |

125 |

100 |

Stainless Steel SS316 |

150 |

250 |

250 |

250 |

250 |

225 |

200 |

100 |

Another factor that could change the working pressure is temperature. The table below shows de-factors temperature ratio:

Temperature (⁰F) |

Temperature (⁰C) |

Brass |

Aluminum |

Stainless Steel |

100 |

37.80 |

1.00 |

1.00 |

1.00 |

150 |

65.60 |

1.00 |

1.00 |

1.00 |

200 |

93.30 |

1.00 |

1.00 |

1.00 |

250 |

121.10 |

1.00 |

0.81 |

1.00 |

300 |

148.90 |

0.97 |

- |

1.00 |

350 |

176.70 |

0.95 |

- |

1.00 |

400 |

204.40 |

0.92 |

- |

1.00 |

450 |

232.20 |

0.90 |

- |

1.00 |

500 |

260.0 |

- |

- |

1.00 |

5. What is Camlock Fitting used for?

Camlock fittings are generally made from four materials. They are stainless steel SS316, steel, brass (HPB57-3), and aluminum ZLD104.

Here’s a table showing the chemical composition of Brass (HPB57-3):

Brass HPB57-3 is a variant of the CW614N and the table of chemical composition is shown below:

Here’s a table showing the chemical composition of Brass (HPB57-3):

Brass HPB57-3 is a variant of the CW614N and the table of chemical composition is shown below:

|

Brass materials are made from a hot forging process, have high corrosion resistance and tensile strength.

Aluminum material is said to be the most abundant metal in Earth’s crust and also a nonferrous metal. Often, other alloys are added to the metal for different reasons. For example, aluminum-copper has about 2-10% copper in it. Copper is added to the metal to increase its strength and reduce ductility. The table below shows the element properties of aluminum:

Aluminum material is said to be the most abundant metal in Earth’s crust and also a nonferrous metal. Often, other alloys are added to the metal for different reasons. For example, aluminum-copper has about 2-10% copper in it. Copper is added to the metal to increase its strength and reduce ductility. The table below shows the element properties of aluminum:

|

Stainless steel SS316 is a nickel-molybdenum-chromium austenitic stainless steel made further to increase the stainless steel material's corrosion resistance. With this addition, the material can withstand harsh temperatures and corrosive environments. The chemical properties are shown in the table below:

|

6. How do you install Camlock Fittings?

|

Camlock fittings are designed to ensure there’s a leak-free operation in systems. The installation process of the fitting is swift and easy. Right connection births the effectiveness of the system during fluid flow, the following steps will guide you when you’re connecting a set of Camlock fittings:

|

For disconnecting the Camlock fittings:

- Depressurize the hose coupling.

- Pull back the locking lever over the cam handles, simultaneously, spin the handles off the couple's body

- Remove the adaptor from the coupler

- Close the coupler by spinning the cam lock handles in direction of the body. You should lock the fitting when there’s no need for users to prevent damage.

camlock fittings catalogue