|

|

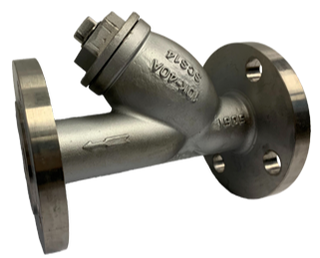

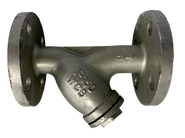

Y-Strainers are devices used to filter or strain out unwanted elements from fluids, steam, or gas. The Y-strainer is y-shaped, hence the name it’s called. The Y-strainer's main duty is to prevent the entrance of particles that could block pipelines and cause other damages from passing through. The Y-strainer is a low-pressure valve used in applications where solid particles that could contaminate the water are common. Y-strainers are made from stainless steel SS316 / CF8M or cast steel materials. The available sizes of Y-strainers range from 1/2” (DN15) to 4” (DN100). Y-strainers are connected using the types NPT, BSPP, and flange end. There are about 4 types of Y-strainers and they can withstand a maximum working pressure of 800 PSI. |

Material Specification |

|

Connection Type |

|

Size |

|

Working Pressure |

|

Y-Strainers Specifications

To learn more about individual product specification, please read the details below:

1. What are Y-Strainers?

|

Y-strainers are mechanical devices used to remove particles and debris from fluids flowing through a system or pipeline. Some fluids usually have particles that could block the pathway or pass through the flow to contaminate others in the system. If this happens, for example, in water systems, the water gets contaminated and useless. Moreover, it could affect other vital components of the connection, hence, the need for y-strainers.

Y-strainers are considered an economical means of straining particles. It’s designed with a wire mesh or perforated straining element and is largely used where the particles found are relatively minimal. However, for fluids with larger particles, Y-strainers are attached to a blow-off connection to strain the debris effectively. They are applied in various industries and devices such as pipes, valves, hoses, meters, steam traps, control valves, regulators, and many more. Y-strainers have the edge over valves as they can be installed in either a horizontal or vertical position. Y-strainers are available in a range of sizes from 1/2” (DN 15) to 4” (DN 100) which are selected according to the application intended. Cast steel and stainless steel SS316 & CF8M are the materials for the Y-Strainers. These materials are high in corrosion resistance and exhibit excellent strength which makes them largely durable. For connection with other systems, the Y-strainers comes in a variety of connection types. More so, Y-strainers can withstand high temperatures ranging from -20⁰C to 230⁰C with a maximum working pressure of 800 PSI. |

The table below shows the component material for Y-Strainer:

British Standard Pipe Parallel (BSPP), National Pipe Thread (NPT), and Flange End are the suitable connection types. However, in cases where the valve will be used for higher pressures, customization of socket or butt weld connection is recommended.

|

2. What is the purpose of the Y-Strainer?

|

Y-strainers are majorly used in industries requiring constant removal of particles or debris from fluids. Y-strainers are largely used as the sole straining device for steam applications worldwide. One major factor contributing to its wide usage in steam applications is the shape which makes it easy for the valve to accommodate the high pressure emitted during steam application.

Also, y-strainers are commonly used in liquid applications. Liquid materials are affected mainly by debris, especially sand and gravel, which causes many damages in liquid applications. Therefore, y-strainers are useful to ensure the liquids flowing are clear and clean. For natural gas and air applications, they work with high pressure as well and the Y-strainer is fit to accommodate the pressure while straining particles. Y-strainers are used in many more industries aside from these few mentioned. Generally, y-strainers help improve system performance efficiency, reduce the maintenance cost, and makes cleaning easy. |

3. Can a Y-Strainer be installed vertically?

|

Y-strainers are very flexible in installation methods. They can be installed horizontally or vertically with the cover cap and screen filter element facing downwards. When installed vertically, it is advisable to direct the inlet flow downwards to allow the Y-strainer to seize particles at the lowest point.

Y-strainers are attached from a diagonal angle to system pipes. They require frequent cleaning to avoid the clogging of particles. For this feature, the basket type strainers have a slight edge over the Y-strainers. Cleaning the screen is easy as the valve is opened and cleaned without necessarily shutting the flow or dismantling it. |

4. How do you clean a Y-Strainer?

|

The Y-strainer has a screen that serves as the sieving device for particles. To clean the Y-strainer screen, close the line and detach the strainer cap. Alternatively, slowly unscrewing the bottom cap for flush cleaning can be done when the operation is normal and safe. There is no particular timeframe for cleaning or performing maintenance checks. However, the pressure drop level should be monitored to guide the strainer screen cleaning.

Pressure drop level measurement is done by pressure gauges placed at the ends of the valve. However, to ensure an accurate measurement, two pressure gauges are recommended to be installed at the inlet and outlet. To clean minor particles, the bottom cap should be flushed or detached from the screen by raising the bottom cover. |

5. How do you determine Y-Strainer mesh size?

The significant component is the mesh filter. Selecting the perfect Y-strainer for the intended applications depends on two factors, mesh size and an understanding of screen basics. Mesh screen and microns are two reading terms used to differentiate the particles that can be sieved in the Y-strainer.

Mesh Size: this defines the number of openings available in one linear inch. For instance, in a 10 mesh screen, the number of openings is 14 available in one linear inch. Also, a 120 smaller mesh has 120 openings available on a linear inch. The rule here is ‘the lesser the mesh number, the lower the particle sizes allowed to flow alongside the fluids and gases to the system.

Micron is the standard of length used to calculate the tiny particles. A micrometer has measured a one-thousandth of a millimeter or one twenty-five thousandth value of an inch.

The table below shows the mesh to micron conversion for Y-strainers:

Mesh Size: this defines the number of openings available in one linear inch. For instance, in a 10 mesh screen, the number of openings is 14 available in one linear inch. Also, a 120 smaller mesh has 120 openings available on a linear inch. The rule here is ‘the lesser the mesh number, the lower the particle sizes allowed to flow alongside the fluids and gases to the system.

Micron is the standard of length used to calculate the tiny particles. A micrometer has measured a one-thousandth of a millimeter or one twenty-five thousandth value of an inch.

The table below shows the mesh to micron conversion for Y-strainers:

|

6. How does Y-Strainers work?

|

The Y-Strainer is very delicate and should be properly installed to ensure efficiency and high performance in removing debris from a fluid flow. Please follow the following instructions when installing the Y-strainer:

|