|

|

|

Material Specification & Working Temperature |

|

Connection Type |

|

Size |

|

Working Pressure |

|

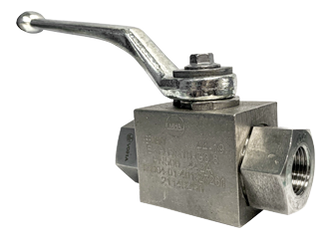

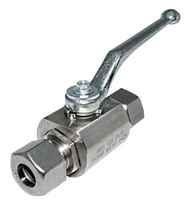

High-Pressure Ball Valves are tools used to control fluid in piping systems and flanges working with the same pressure load or flange connection. These valves have a handle for controlling the fluid flow either for full open or full close flow.

The valves' fluid flow is closed when the ball’s holes are at 90-degrees and open when the ball is working with the flow. They have a working pressure of a maximum of 700 Bar and are made of steel and stainless steel elements. They are also in different sizes ranging from 1/8 inches to 4 inches.

The valves' fluid flow is closed when the ball’s holes are at 90-degrees and open when the ball is working with the flow. They have a working pressure of a maximum of 700 Bar and are made of steel and stainless steel elements. They are also in different sizes ranging from 1/8 inches to 4 inches.

|

|

STUDY CATALOGUE HERE |

|

1. What are Hydraulic Ball Valves made of?

|

The high-pressure ball valve has 5 major parts – the body, the ball, the o-ring, the ball seats, and the ball seats and the steam.

The code for the stainless steel material is 442A while that of popular carbon steel is 112A, 192A, or 212A. It’s important to be sure about the pressure and temperature level before purchasing the ball valve because failure to do this results in the exclusion of the valve warranty. In case the High-Pressure Ball Valve is used for a gas application, the material code is either 44aA or 44HA. |

The table below shows the material codes description combinations:

|

2. Do Ball Valves restrict flow?

|

The ball valve has a floating ball that serves as flow control. The ball is closed when the valve handle is pivoted at 90-degrees. When this is done, the flow of fluid automatically stops, however, the valve handle is changed to the open, the ball holes get in line with the flow to allow the continuous connection of fluid outpour. Furthermore, they are produced with top-notch materials which make them highly durable and efficient through the years of use.

|

3. How does a Hydraulic Ball Valves work?

Connection types for valves' ends are numerous and they are outlined with consideration to the system installation. Amongst the common valve ends standards are:

- British Standard Pipe Parallel Thread (BSPP): This standard is common in the European, Asian, and Australian continents. For this threaded fitting, a bonded seal ring serves as the sealant and it’s placed in the middle of the male and female face flange, after that, fitted into the perfect position.

- National Pipe Thread (NPT): these are popularly used for pressure calibration machines in the United States. They have tapered and straight thread which can be used for diverse purposes. This sealing is possible due to the lack of roundness principle.

- Compression Type (DIN 2353 / ISO 8434-1): DIN 2353 and ISO 8434-1 are standards used for hydraulic fittings, with similar 24 cutting rings, assembly with nut, and 24 cone connector end. Deutches Institut fϋr Normung (DIN) is a German standardization organization established in 1917. ISO represents the International Organization for Standardization.

- Welding end: Weld End is a form of connection placed at the end of pipes and tubes to allow attaching to other pipes or components. It can be in the form of socket weld, butt weld, etc. welding involves using heat to melt metals or thermoplastics parts together. After that, the welded parts are left to cool down.

4. What is the purpose of Ball Valve?

|

High-Pressure Ball Valve is used in various industries for controlling flows of fluids and other elements. Some of its application is in:

|

One may wonder why these ball valves aren’t used in the food, beverage, and pharmaceutical industry. This is because the valves are designed in a way that may seem difficult to clean the parts thoroughly, and using unclean mechanical tools for the production of edibles may be hazardous to human health.

5. How do you lock a Hydraulic Ball Valve?

The high-pressure ball valve can be used with accessories which are specially designed to work with the specifications of the system being used. These are available on request and they help increase the performance of the system. Here are some of the accessories available:

Before ordering an actuator, you have to give the temperature level, working pressure, and service medium. These will help design the right actuator for your system. After installation, the valve handle should be removed before usage begins.

- Detent: the detent is a locking device that makes the operation of the valve easy. The detent device can be used at an end or both ends. A detent is made in two types – float detent and self-cancelling detent. It functions similarly to locking mechanisms.

- Locking Devices: with a locking device installed on your valve, the safety of the valve is guaranteed even when an unintentional actuation is made. They are made from steel and stainless steel materials. Majorly, they avoid accidental actuation and can be additionally locked if a padlock is placed on the valve. Therefore, before using a locking device, the operator has to unlock the padlock with a key to enable usage.

- Limit Switch: A limit switch is a device that shows the actual position of a valve, whether opened or closed. This will help ascertain the current situation in the system without any doubt.

- Electric and Pneumatic Actuator: an actuator is a device in a system that serves as the handle for controlling the system and opening of the ball valve. The actuator works with a form of energy which can be electric, pneumatic, or human energy. An electric actuator uses the electric actuator to operate in a hydraulic system. A pneumatic actuator on the other hand works with the energy from pressurized air to run. It is very safe and more reliable than other actuator types.

Before ordering an actuator, you have to give the temperature level, working pressure, and service medium. These will help design the right actuator for your system. After installation, the valve handle should be removed before usage begins.

6. What is the installation process for a Ball Valve?

Before trying to install a ball valve, you have to examine the checklist and use it as a guideline during and after the installation process. To simplify the process, the checklist is listed below:

Before Installation:

Before Installation:

- To ascertain whether the designs of the valves are compatible, there’s a need to carry out proper checking before installing them at all.

- It is recommended that experts should do the installation of the valve while the ball valves and other pipes are free from pressure. While incorporating the pipelines, they must be done without tension on the fittings.

- All pipelines should be rinsed before installation as the presence of debris and other dirt can affect the inner parts of the pipes resulting in malfunction or complete damage of valves.

|

During Installation:

After Installation:

These instructions must be duly followed to avoid leakages when the flow of fluids begins. And inspection must be carried out after assembly. |

HYDRAULIC BALL VALVES CATALOGUE