|

|

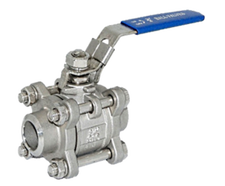

Ball valves are an essential instrument in different industries. They are the most used valve types due to their versatility. Ball valves are designed with quarter-turn valves which give easy control and operation. Low pressure ball valves are produced in three different types, they are, 1 piece, 2 piece, and 3 piece ball valves. These valves are used generally in oil, gas, and water systems. Low pressure ball valves can withstand a maximum working pressure of 1000 PSI (1 and 3 piece ball valve) and 2000 PSI (2 piece ball valve). The connection end types used by low pressure ball valves are threaded (NPT/BSPP) and welding (Butt Weld/Socket). They are available in sizes ranging from 1/4” to 4” and made from brass, carbon steel (A105), and Stainless steel SS316. |

Material Specification |

|

Connection Type |

|

Size |

|

Working Pressure |

|

Low Pressure Ball Valves Specifications

To learn more about individual product specification, please read the details below:

1. What is a ball valve used for?

|

Valves are devices that help regulate and control fluid flow in systems. Valves can be for opening, closing flow pathways, or prevention of backflow of fluids. Valves are used in different ways in industries. Valves are of different types, such as ball valves, butterfly valves, globe valves, check valves, gate valves, ball valves, etc.

Ball valves are a ball-shaped shut-off valve that controls fluid or gas flows in devices. A ball valve is beneficial because it offers tight sealing and prevents leakages in systems. Ball valves are classified as high pressure ball valves or low pressure ball valves. The significant distinction between these two valves is the pressure level each can accommodate. High pressure ball valves can withstand a higher level of pressure than low pressure ball valves. |

Low pressure ball valves are divided into reduced bore ball valve and full bore ball valve. They control the flow of fluids in low pressure systems. They work on a maximum of 2000 PSI pressure and temperature ranging from -29 ⁰C to 150 ⁰C.

Low pressure ball valves are mostly produced in sizes ranging from 1/4” to 4”. These sizes are based on the type of application the device is used for. Low pressure ball valves are made of stainless steel, carbon steel, and brass material, however, low pressure ball valves are mostly available in stainless steel material due to its high corrosion resistance and strength. Low pressure ball valves can work with a maximum pressure of 2000 PSI and accommodate temperature levels ranging from -29⁰C to 150⁰C.

Low pressure ball valves are mostly produced in sizes ranging from 1/4” to 4”. These sizes are based on the type of application the device is used for. Low pressure ball valves are made of stainless steel, carbon steel, and brass material, however, low pressure ball valves are mostly available in stainless steel material due to its high corrosion resistance and strength. Low pressure ball valves can work with a maximum pressure of 2000 PSI and accommodate temperature levels ranging from -29⁰C to 150⁰C.

2. What are the types of Low Pressure Ball Valves?

Low pressure is of three different types. They are 1 piece, 2 piece, and 3 piece low pressure ball valves.

1 piece low pressure ball valves: this low pressure ball valve has end connections and a body made of one piece of material. When used in systems, the valve trim and seals are placed into one end connection of the system. The valve ensures the leakage rate is minimal due to its solid, cast body. However, the line size of the low pressure ball valves is unequal with the port size. This is produced as a reduced bore.

2 Piece Ball Valve: the 2 piece low pressure ball valve consists of two distinct pieces that are to be joined by connected or threaded bolts with flanges. Although this ball valve type has a higher risk of leakage, however, it is also a plus because it aids the easy detachment of the valve when maintenance or repair needs arise.

3 Piece Ball Valves: this ball valve type has three pieces, a body, and two end caps. They are connected to pipe ends either by welding, threading or with flanges. It helps avoid line shutdown during maintenance in systems and work as separators of valve connection port from the body.

1 piece low pressure ball valves: this low pressure ball valve has end connections and a body made of one piece of material. When used in systems, the valve trim and seals are placed into one end connection of the system. The valve ensures the leakage rate is minimal due to its solid, cast body. However, the line size of the low pressure ball valves is unequal with the port size. This is produced as a reduced bore.

2 Piece Ball Valve: the 2 piece low pressure ball valve consists of two distinct pieces that are to be joined by connected or threaded bolts with flanges. Although this ball valve type has a higher risk of leakage, however, it is also a plus because it aids the easy detachment of the valve when maintenance or repair needs arise.

3 Piece Ball Valves: this ball valve type has three pieces, a body, and two end caps. They are connected to pipe ends either by welding, threading or with flanges. It helps avoid line shutdown during maintenance in systems and work as separators of valve connection port from the body.

3. What is a 3-way Ball Valves used for?

Ball valves are designed in the form of quarter-turn valves and a rotating ball that controls the flow of fluids in pipelines and systems. Ball valves are in different types, however, the two-way and three-way valves are the most common types.

3-way ball valves are also known as multi-port ball valves. A three-way ball valve is designed to have three openings or ports for fluids and gases to flow through. These openings can either be 1 inlet, two outlets, or vice versa according to the direction of flow and system connection. These valves are cost-effective because there’s room for closing and flow direction control in a single valve.

Three-way valves can be used in diverse ways to control fluids such as:

One important factor that determines the specific work of a three-port valve is the design difference. Three-way valves are either designed L-pattern or T-pattern flows, however, the most common pattern flown is the L-pattern.

3-way ball valves are also known as multi-port ball valves. A three-way ball valve is designed to have three openings or ports for fluids and gases to flow through. These openings can either be 1 inlet, two outlets, or vice versa according to the direction of flow and system connection. These valves are cost-effective because there’s room for closing and flow direction control in a single valve.

Three-way valves can be used in diverse ways to control fluids such as:

- Combine fluid flow from two places

- Separate fluids from one source to two different sources

- Completely stop the flow of fluids

- Redirect flow from one source to another source entirely

- Rotate flow of fluids to stop in one source and continue in the other.

One important factor that determines the specific work of a three-port valve is the design difference. Three-way valves are either designed L-pattern or T-pattern flows, however, the most common pattern flown is the L-pattern.

|

L-pattern flow balls are often called diverter valves or 90-degree balls because they allow flow from one inlet to two different outlets. L patterns may have handles that can turn 90 degrees, 180 degrees, or more than 180 degrees. This defines the flow direction for the valve.

|

T-pattern flow balls also referred to as mixing valves are used mainly to combine fluids flowing from two different sources. These combined fluids then pass out through one outlet. Based on the allowed handle motion, they can divert, mix, or allow a straight-way passage of fluid. They are installed at the base of the valve body to serve as the outlet port for fluids.

|

4. What are the differences between the Ball and Gate Valves?

|

Ball and gate valves are types of valves used to control fluid flow in systems. These two valves are popularly used in various industries, however, there are some differences to explore.

The major difference between the ball and gate valve is the structural design. The ball valve has a stem and ball. The floating ball works with an opening inside of it to allow free flow when the valve is on unlike the gate valves that are controlled with a gate. The gate is circular or rectangular and it is raised when the valve is opened to allow the flow of fluids. |

5. What are the installation steps for a Low Pressure Ball Valve?

Proper installation of ball valves is instrumental to the effective functioning of the system. Here are steps to guide you:

STEP 1

Thoroughly clean the inner and outer parts of the pipes.

STEP2

Properly align the pipes placed on the two ends.

STEP 3

Ensure the pipes placed are well aligned and compatible because this could disrupt the tightness and functioning of the valve.

STEP 4

Where there’s a lack of support for the pipes, the temporal fixing can come to play to reduce the burden on the valves.

STEP 5

Connect the valves using thread sealants.

STEP 6

Ensure the valves are well-tightened.

STEP 1

Thoroughly clean the inner and outer parts of the pipes.

STEP2

Properly align the pipes placed on the two ends.

STEP 3

Ensure the pipes placed are well aligned and compatible because this could disrupt the tightness and functioning of the valve.

STEP 4

Where there’s a lack of support for the pipes, the temporal fixing can come to play to reduce the burden on the valves.

STEP 5

Connect the valves using thread sealants.

STEP 6

Ensure the valves are well-tightened.

low pressure ball valves catalogue