|

|

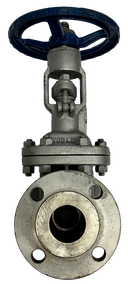

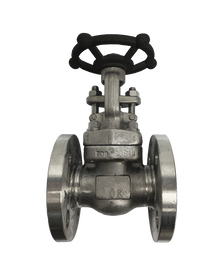

Gate valves are made following the ASME B16.34 / API602 standards. Gate valves are low pressure valves used to stop fluid flow. The gate valve is designed with a gate or wedge type disc to control the valve opening or closure. The gate valves have a wheel-shaped handle with seat sealing in metal to metal. Gate valves are used for various applications and come in different types. Gate valves are available in sizes ranging from 3/4” to 6”. The materials used for gate valves are Forged Steel A105, Cast Steel, Stainless Steel SS316, and Cast Iron. Gate valves can withstand working pressure between 150#, 200#, and 800#. For gate valves, various end connection types are used. |

Material Specification |

|

Connection Type |

|

Size |

|

Working Pressure |

|

Gate Valves Specifications

To learn more about individual product specification, please read the details below:

JIS 10K Cast Iron Gate Valve |

ANSI 150# Cast Steel Gate Valve |

ANSI 150# Forged Steel Gate Valve |

Threaded End Forged Steel Gate Valve |

Welded End Forged Steel Gate Valve |

1. What is the function of Gate Valve?

|

Gate valves are low pressure valves used to shut down the flow of fluid in systems. The gate ball valve is made following the ASME B26.34 / API602 and available in sizes ranging from 3/4” to 6”. Working pressure for gate ball valves varies, however, the maximum pressure is 800#. Gate valves are made of various materials such as cast Iron, stainless steel SS316, cast iron, and forged steel.

Gate valves are mainly designed to block the flow of process fluids in a system installation. They are either placed in a fully opened or fully closed position. Gate valves are low pressure valves designed to have a maximum pressure rating of 150 PSI. The valve is designed with a wedge type disc or gate placed at the center of the valve and it blocks process fluid from flowing through the valve. The gate valve is designed as a multi-turn valve, that is, the transformation from opened to closed position occurs after multiple turns which allow a slow movement to avoid water hammer effects. The threaded stem does this and this is the place for the upward and downward movement of the gate during operation. Gate valves are used in different industries using fluid services such as hydrocarbons, air, fuel, steam, lube oil, and steam. |

2. What is a Gate Valve used for?

Gate valves are linear motion valves and are mostly applied in plant processing. The gate valve is detached whilst the valve is fully opened. A normal gate valve does not block fluid during flow. This reduces the rate of pressure loss and the creation of a free bore. Also, after the valve is fully closed, tight-sealing only occurs when the disc and seats achieve a 360⁰ surface contact.

Gate valves aren’t suitable to serve as control or regulating valves because the precision of flow control is unrealistic. When the valve is partly opened, the flow rate is at a high velocity which may result in erosion of the disc and the seating surface. When this happens, the vibration and sound rate increases drastically.

Gate valves are produced in different body types. These types are enumerated below:

Gate valves aren’t suitable to serve as control or regulating valves because the precision of flow control is unrealistic. When the valve is partly opened, the flow rate is at a high velocity which may result in erosion of the disc and the seating surface. When this happens, the vibration and sound rate increases drastically.

Gate valves are produced in different body types. These types are enumerated below:

Type of Body Bonnet Joint |

Type of Disc |

Type of Stem Movement |

|

|

|

3. How do you identify a Gate Valve?

The gate valve is shaped like a wedge or knife and it is higher than the globe valve when fully opened; however, the gate has a smaller face to face length dimension. There are several types of gate valve bonnet as per below:

Type of Body Bonnet Joint |

Features |

Bolted Bonnet |

|

Pressure sealed bonnet |

|

Screwed bonnet |

|

Welded bonnet |

|

4. Which is a type of Gate Valve?

There are three major types of gate valves. They are:

- Solid taper wedge: the solid taper wedge is the commonly used type of gate valve due to its simplicity and strength. Any valve with this solid taper wedge is very flexible and fit to be installed in any position as required by the system. However, one major drawback of the solid taper wedge is changing seat alignment as the pipe load increases. More so, this type is prone to leakages of fluid and when exposed to high temperature, the wedge is susceptible to thermal locking. Thermal locking is a term used to define a state of wedge disc getting stuck between valve seats and expanding the metal. Solid taper wedges are best used for low pressure to moderate temperature systems.

|

5. What do Gate Valves fail?

|

Gate valves are designed with a disc placed at the center of the valve. This disc moves as the valve handles are placed in an open position. As time sets in, the valve matures in terms of age and the disc tends to stick. When the valve is closed, fluid flow occurs because the disc has stuck while in an open position. The disc may remain in that position after opening the valve. When this happens, the gate valve has failed to carry out its main objective which is to block fluid flow when closed.

Another problem gate valves face is corrosion and wear. The gate valve is prone to wear often and when corrosion happens, it could cause sticking. A forceful turning of the valve handle will lead to breaking the stem and general valve damage. |

GATE VALVE CATALOGUE