|

|

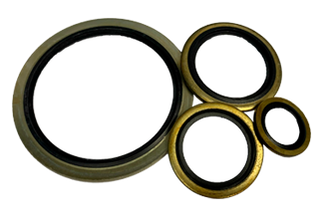

Dowty seals are also referred to as Bonded Seals. Dowty seals are also referred to as Dowty washers or bonded seals. Dowty seals are washer types used in tubes, flanges, or pipeline installation to tighten the connection around a screw or bolt. A washer is a disk-shaped thin plate used to share the load of a bolt, nut, or other fastener types. Dowty seals are applied in high-pressure systems as an alternative to other sealing types. Also, based on sizes, Dowty seals can withstand a working pressure of 20,000 PSI. Generally, they are used in hydraulic, mechanical, and pneumatic systems. |

Material Specification |

|

Size |

|

Size Specification |

|

1. What are Dowty Seals?

|

In a pipeline or tube installation, seals are useful to secure ends of the installation. During operation, fluids can get leaked, which may damage the system, hence the need for seals. Seals are mechanisms used to secure the openings of pipe ends and joints to avoid leakages, contamination of fluid, and generally, the system's damage. Seals are used in various industries for various purposes. Examples of these seals include O-rings, Gaskets, Bellow seals, Labyrinth seals, face seals, lip seals, etc.

Dowty seals are used to secure end connections when other seals are unavailable. It is made up of a metallic ring and an elastomer sealing pad joined together. The metallic ring is made of steel material and the elastomer sealing pad acts as a gasket and is made of nitrile rubber. Bonded seals ensure the pipeline connection is tightly sealed together against any leakages |

2. What are Dowty Seals made of?

The elastomer sealing is nitrile rubber. NBR is a common rubber material made from acrylonitrile and butadiene. They are used in various industries for production and popular due to their resistance to chemicals, oil, and fuel. Some of its uses are for gaskets, oil seals, belts, O-rings, oil seals, etc.

The table below shows the properties of the material:

The table below shows the properties of the material:

|

Dowty seals' metallic ring can be made from various materials such as stainless steel, brass, aluminum, etc.

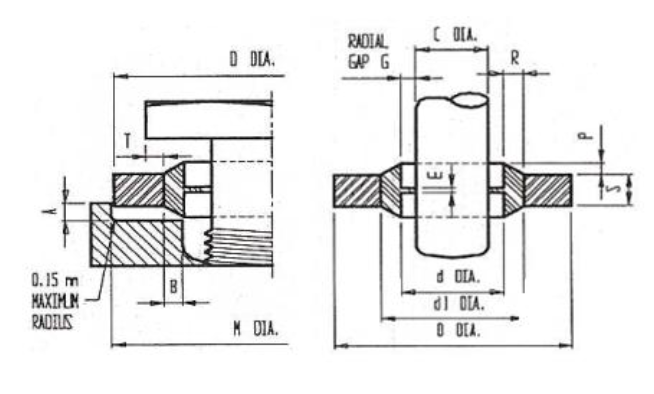

3. What are the sizes of Dowty Seals?

Dowty seals are available in Metric and Imperial sizes. More so, they can work with temperature levels ranging from -30 ⁰C to 120 ⁰C.

Thread Size M |

Size Reference |

d +/-0.13 |

C Centralizing Lip |

C Centralizing Lip |

E +/-0.05 |

P +/-0.13 |

R +/-0.10 |

d1 +/-0.10 |

D +0.13 |

S +/-0.10 |

M8 |

866 |

8.70 |

6.40 |

+0.25/-0 |

0.35 |

0.38 |

0.20 |

10.40 |

14.00 |

1.00 |

1/8 BSP |

820 |

10.37 |

8.26 |

+0.25/-0 |

0.35 |

0.38 |

0.20 |

11.84 |

15.88 |

2.00 |

M10 |

708 |

10.70 |

8.05 |

+0.25/-0 |

0.35 |

0.38 |

0.20 |

12.40 |

16.08 |

1.50 |

M12 |

867 |

12.70 |

9.73 |

+0.25/-0 |

0.35 |

0.38 |

0.20 |

14.10 |

19.00 |

1.50 |

1/4 BSP |

821 |

13.74 |

11.18 |

+0.25/-0 |

0.35 |

0.38 |

0.20 |

15.21 |

20.57 |

2.00 |

M14 |

868 |

14.70 |

11.39 |

+0.25/-0 |

0.35 |

0.38 |

0.20 |

16.40 |

22.00 |

1.50 |

5/8 |

869 |

16.51 |

12.90 |

+0.25/-0 |

0.35 |

0.38 |

0.20 |

18.75 |

25.40 |

2.00 |

M16 |

870 |

16.70 |

13.41 |

+0.25/-0 |

0.35 |

0.38 |

0.20 |

18.40 |

24.00 |

1.50 |

3/8 BSP |

823 |

17.28 |

14.76 |

+0.25/-0 |

0.35 |

0.38 |

0.20 |

18.75 |

23.80 |

2.00 |

11/16 |

871 |

18.16 |

14.50 |

+0.25/-0 |

0.35 |

0.38 |

0.20 |

19.69 |

25.40 |

2.50 |

M18 |

872 |

18.70 |

14.76 |

+0.25/-0 |

0.35 |

0.38 |

0.20 |

20.40 |

26.00 |

1.50 |

M20 |

873 |

20.70 |

16.76 |

+0.25/-0 |

0.35 |

0.38 |

0.20 |

22.50 |

28.00 |

1.50 |

1/2 BSP |

825 |

21.54 |

18.24 |

+0.25/-0 |

0.35 |

0.38 |

0.20 |

23.01 |

28.58 |

2.50 |

M22 |

874 |

22.70 |

18.74 |

+0.25/-0 |

0.35 |

0.38 |

0.20 |

24.40 |

30.00 |

2.00 |

5/8 BSP |

826 |

23.49 |

20.27 |

+0.25/-0 |

0.35 |

0.38 |

0.20 |

24.97 |

31.75 |

2.50 |

M24 |

875 |

24.70 |

20.11 |

+0.25/-0 |

0.35 |

0.38 |

0.20 |

26.40 |

32.00 |

2.00 |

3/4 BSP |

827 |

27.05 |

23.83 |

+0.25/-0 |

0.35 |

0.38 |

0.20 |

28.53 |

34.93 |

2.50 |

7/8 BSP |

829 |

30.81 |

27.51 |

+0.37/-0 |

0.35 |

0.38 |

0.20 |

32.29 |

38.10 |

2.50 |

1 BSP |

830 |

33.89 |

29.92 |

+0.37/-0 |

0.35 |

0.38 |

0.20 |

36.88 |

42.80 |

3.20 |

1 1/4 BSP |

832 |

42.93 |

38.45 |

+0.37/-0 |

0.35 |

0.38 |

0.20 |

45.93 |

52.38 |

3.20 |

1 1/2 BSP |

833 |

48.44 |

44.45 |

+0.37/-0 |

0.35 |

0.38 |

0.20 |

51.39 |

58.60 |

3.20 |

1 3/4 BSP |

934 |

54.89 |

50.42 |

+0.37/-0 |

0.35 |

0.38 |

0.20 |

58.30 |

69.85 |

3.20 |

2 BSP |

836 |

60.58 |

56.26 |

+0.37/-0 |

0.35 |

0.38 |

0.20 |

63.63 |

73.03 |

3.20 |

2 1/4 BSP |

838 |

66.68 |

62.36 |

+0.37/-0 |

0.35 |

0.38 |

0.20 |

69.98 |

79.50 |

3.20 |

2 1/2 BSP |

839 |

76.08 |

71.50 |

+0.37/-0 |

0.35 |

0.38 |

0.20 |

79.38 |

90.17 |

3.20 |

4. What are the benefits of Dowty Seals?

|

Dowty seals are very useful in the installations of various systems. The advantages of the seal are listed below:

|

5. What is the torque value for the Dowty Seals?

The table below shows the torque value for Dowty seals:

Thread Size Metric |

Thread Size Imperial |

Thread Size BSP |

Torque Required Nm |

Torque Required lbf.in |

Up to 8 |

5/16 |

- |

5.3 |

47 |

10 |

3/8 |

1/8 |

7.1 |

63 |

11 |

7/16 |

- |

11.8 |

105 |

12 |

1/2 |

1/4 |

15.8 |

140 |

14 |

9/16 |

.60 x 19 |

22.6 |

200 |

16 |

5/8 |

3/8 |

30.5 |

270 |

18 |

3/4 |

.75 x 14 |

40.7 |

360 |

20 |

.825 |

1/2 |

56.5 |

500 |

22 |

7/8 |

5/8 |

67.8 |

600 |

24 |

1 |

- |

73.4 |

650 |

27 and above |

1.041 |

3/4 |

79 |

700 |

6. Can you screw NPT into BSPP?

|

NPT threads are also known as National Pipe Thread and they are the common thread type used in the USA. NPT threads are made in Male Pipe Threads (MPT) and Female Pipe Threads (FPT) attached and compressed to create a seal.

BSPP threads are also called British Standard Pipe Parallel. BSPP threads are often used during mechanical joining. In other words, they are applied when the connection doesn’t require a water-tight seal or the threads sealing against each other. Seal types such as O-ring (elastomer), soft metal seal, or hard metal seal like Dowty seal are used in this connection. To be more explicit, the O-ring is positioned between the fitting sides. Screwing NPT into BSPP can be answered in two ways. The first is that male NPT can be screwed into Female BSPP. This can only be possible in applications using low pressure and a Teflon tape to seal the connection. However, the male NPT fitting threads more into the vertical threaded BSPP female fittings. Screwing female NPT into male BSPP is not recommended because of the main difference between both. The female NPT is tapered while the male BSPP is tapered and this makes the connection unrealistic. |

dowty seals catalogue