Let's learn more about KPL Industry

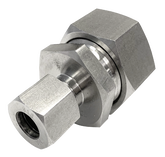

KPL Industry is a manufacturer of hydraulic system components, especially high-pressure valves and fittings. They are classified amongst the top producers and service providers of flow control products in the market globally. They place much emphasis on the quality of products and top-notch designs to ensure the satisfaction of clients with their products.

The company was established in 2008 and since then, it has maintained the trust of many clients through the offer of services provided. The industry ensures the proper testing of all products before being distributed into the market. This makes the manufacturing of quality products at a minimal cost possible.

The company was established in 2008 and since then, it has maintained the trust of many clients through the offer of services provided. The industry ensures the proper testing of all products before being distributed into the market. This makes the manufacturing of quality products at a minimal cost possible.

1. What is history of the KPL Industry?

KPL Industry was established in August 2008 and since then has specialized in the production of high-pressure valves and fittings. The industry is situated in South Korea as one of the fastest-growing technological countries in the world. This keeps the company at the frontline of the production of various high-pressure valves and fittings used in hydraulic systems and pipeline connections. Excellent customer service, extended capability range, and unique quality products are factors contributing to the increased relevance of the KPL brand in the market today.

The list below shows the specific industries applying the various products of the KPL Industry in their activities:

These aforementioned industries are into essential services and with the technological growth in the world daily, the systems and mechanisms used are modified and become more sophisticated. Hence, there is a requirement to constantly purchase from a company aware of these growths and advancements.

The list below shows the specific industries applying the various products of the KPL Industry in their activities:

- Agriculture

- Drilling

- Shipbuilding and Ship Repair

- Power Plant

- Nuclear Power Plant

- Oil and Gas

These aforementioned industries are into essential services and with the technological growth in the world daily, the systems and mechanisms used are modified and become more sophisticated. Hence, there is a requirement to constantly purchase from a company aware of these growths and advancements.

2. What does KPL Industry deliver?

KPL industry commits itself to constant learning and developments to attain customer satisfaction and formulate quality policies for effective management execution in the establishment. To meet the client requirement and satisfaction with prompt delivery of goods, the KPL industry’s core lies in quality innovation with the main goal of quality first in mind.

The final aim of their quality policy execution is to achieve these points listed below:

The major products of the KPL industry are listed below:

The final aim of their quality policy execution is to achieve these points listed below:

- Zero product defect rate: this goal is targeted at producing a quality product with a long durability level and to help clients reduce maintenance and repair costs.

- Listen to customer’s complaints and needs with a prompt response: the products offered are used by customers who evaluate the effectiveness and efficiency. A failure to listen to the requirements of the clients will lead to neglect of the product in the market.

- Constant improvement of devices to enhance product quality: a need to constantly carry out research on new materials and manufacturing equipment to make use of those that could help enhance the quality of products by the industry.

- Increase raw material quality checking layer to produce an effective end product: raw materials have different chemical combinations and compositions. For some with weak qualities, other elements are added to improve the quality, hence the need to continuously enhance the re=aw materials used in manufacturing the products.

The major products of the KPL industry are listed below:

3. Is the KPL brand certified?

The KPL Industry is a certified brand that has won many medals in their specialized area. More so, the KPL products are designed following major international standards and thereafter approved by international approval certificates. These standards are listed below:

These standards specifications and dimensions are applied in the manufacturing of their products. The industry uses the progress of production classified from step 1 to step 10. This is shown in the table below:

- ISO 9001

- PED approved

- ISO 14001

- Rina workshop certificate

These standards specifications and dimensions are applied in the manufacturing of their products. The industry uses the progress of production classified from step 1 to step 10. This is shown in the table below:

Process 1 |

Process 2 |

Process 3 |

Process 4 |

Process 5 |

Raw material |

Chemical analysis |

Measuring weight and dimension size |

Material grade check |

Normalizing |

Quantity control check |

Preservation of analysis |

Cutting product surface |

Weight measuring |

Tempering |

Visual product stock & dimension check |

Certificate checking of chemical composition |

Product marketing |

Temperature reading & control |

Quenching & product temoering |

- |

- |

- |

Mechanical test |

Solution treatment |

Process 6 |

Process 7 |

Process 8 |

Process 9 |

Process 10 |

Dimension test |

Description marking |

Preserve check |

Packing requirement |

Arrangement dispatch shipping |

Visual testing |

Marking of size |

Coating, Tectyl 506, etc |

Physical Packing inspection |

Checking documents |

Non-destructive test |

Lot no. marking |

- |

- |

Certificate of origin |

For more inquiries about KPL products, please refer to our product pages listed below: