Let's learn more about MHA Zentgraf

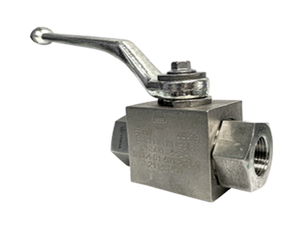

MHA Zentgraf was established in 1978 and they specialize in the production of high pressure ball valves. They are classified as one of the best valve producers around the globe. The ball valves produced are made in different sizes to enable compatibility with a wider range of systems in different industries. The sizes of the high pressure ball valves range between 1/8” to 8” or DN4 to DN200. The valves are designed to withstand a maximum pressure of 2,000 bars. Also, the company has produced valves with different connection end types. More so, the products are manufactured following the specifications of different standards.

1. What is history of the MHA Zentgraf Company?

The MHA Zentgraf is a company specializing in the production of various high pressure ball valves established in the year 1978. MHA Zentgraf valves are designed to meet several standards such as ANSI B1.20.1 NPT, ISO 6162-1/2, ISO228-BSPP, ISO 8434-1, ISO 6164, and many more.

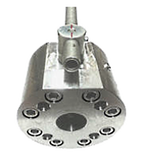

The ball valves are majorly made from stainless steel and steel materials. Also, there’s an opportunity for customization of materials as the need of the application is in materials like Hastelloy, duplex and super duplex. Since the establishment of the company, over 30,000 ball valves, check valves, accessories, and control valves have been manufactured.

The standard ball valves are produced in different designs and have an opportunity for attachment with accessories such as actuators, locking devices, assembly bores, limit switches, detent, and lots more.

The ball valves are majorly made from stainless steel and steel materials. Also, there’s an opportunity for customization of materials as the need of the application is in materials like Hastelloy, duplex and super duplex. Since the establishment of the company, over 30,000 ball valves, check valves, accessories, and control valves have been manufactured.

The standard ball valves are produced in different designs and have an opportunity for attachment with accessories such as actuators, locking devices, assembly bores, limit switches, detent, and lots more.

2. Is MHA Zentgraf Company Certified?

The MHA Zentgraf Company has been certified after meeting a series of requirements such as DIN EN ISO 14001 environmental standards, and dependable pressure equipment directive DIN EN ISO 9001 and CE standards. Further, procedure operation tests are taken on the products through inspection and supervision by recognized classification establishments.

The test certificates provided by the MHA Zentgraf company are made following the DIN EN 10204 3.2 and DIN EN 10204 3.1 standards. This is met under the practice codes AD-Merkblatt HP 0. The fire-safe ball valves produced by the company are made following the API 6 FA, ISO 10497, and BS 6755 T.2 specifications. Other standards are shown below:

The test certificates provided by the MHA Zentgraf company are made following the DIN EN 10204 3.2 and DIN EN 10204 3.1 standards. This is met under the practice codes AD-Merkblatt HP 0. The fire-safe ball valves produced by the company are made following the API 6 FA, ISO 10497, and BS 6755 T.2 specifications. Other standards are shown below:

|

|

3. What is the objective of the MHA Zentgraf Company?

The objective of the MHA Company complies with the European Foundation for Quality Management Model (EFQM) as a guideline for employee relations and company major activities. These major figures provide an evaluation slate daily for improvements on the company’s activities.

The employees operate on the exact goal through Balance Score Card (BSC). Further, LEAN techniques and six sigma guides in agreeing on the right decisions to improve performance and efficiency in harsh circumstances.

The company has realized the need of the customers in product demands and this guides during production to help maintain the relevance of the company in the market. This also helps increase the notion of being a reliable partner in the industry. The use of technology-based plans and methods gives easy access for evaluation and analysis of solutions that could be adopted.

The employees operate on the exact goal through Balance Score Card (BSC). Further, LEAN techniques and six sigma guides in agreeing on the right decisions to improve performance and efficiency in harsh circumstances.

The company has realized the need of the customers in product demands and this guides during production to help maintain the relevance of the company in the market. This also helps increase the notion of being a reliable partner in the industry. The use of technology-based plans and methods gives easy access for evaluation and analysis of solutions that could be adopted.

4. What are the strengths of the MHA Zentgraf?

The major goal of the MHA company is to create an outstanding service and peculiar product quality for its customers. The major strengths of the company are enumerated below:

- Product Availability: the company has produced over 30,000 ball valves and they are readily available for purchase and use in the market. More so, the time for the production of ordered materials ranges between four to six weeks.

- High Corrosion Resistance: the various products of MHA Zentgraf are made with top-notch materials which are very high in corrosion resistance. This makes the products last longer with reduced cost operation.

- Represented in four time zones: The company has establishments in the four world time zones which makes the employees available for consultation all round the clock.

- Languages: the company operates with seven major languages which are English, French, German, Italian, Chinese, Spanish, and Russian.

- Large Customer base due to Satisfaction: the company ensures the customers’ needs are constantly met with room for improvements.