|

|

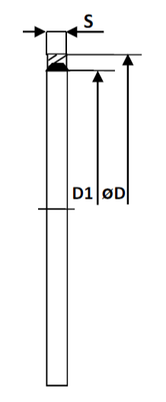

GS Bonded Seal is also referred to as GS-Hydro Retain Ring and they are applied in piping systems. The GS Bonded Seal is designed to work with a maximum working pressure between 350 to 450 bars. However, when there’s a special order, the GS Bonded Seal can work with a maximum pressure of 690 bars. GS Bonded Seal is designed to work with high-pressure piping systems made from various materials, including titanium, mild steel, duplex, stainless steel, and other materials with an elongation ability of 20%. GS Bonded Seals are made following ISO 6162-2 and ISO 6164 standards. They are available in sizes ranging from 1/2” to 8” and are made from stainless steel SS302. |

Material Specification |

|

Design Standard |

|

Size |

|

Size available |

|

Working Pressure |

|

1. What is GS Bonded Seals?

|

GS Bonded Seal is used in pipeline systems and is designed according to the International Standard Organization (ISO) standards 6162-2 and 6164. The seal comprises a rubber seal (NBR) and metallic ring joined together. They are majorly used in piping systems with no welding option and applied in offshore, marine, and mining systems. GS Bonded Seals are made in various sizes ranging from 1/2 inches to 8 inches and made from SS302.

GS Bonded Seals are designed to work with a maximum pressure within 350 to 450 bars, however, an order for an increase in the working pressure can be made available and the seal will work with maximum pressure up to 690 bars. Generally, GS Bonded Seals are suitable for use in high-pressure applications and systems. |

2. What is GS Bonded Seals made of?

|

GS Bonded Seals are seals made from natural rubber (NBR) and a metallic ring made from SS302 material.

Nitrile Rubber also called NBR is an elastomer material. This elastomer material is the most used in the seal field. The material has great benefits, hence, its wide popularity and usage. NBR material can withstand temperature levels between -35⁰C to +120⁰C (-30⁰F to +250⁰F). Also, NBR has great resistance to petroleum products, flame retarded fluids (HFC, HFA, HFB), wear and tear, abrasion, and compression. Although Nitrile rubber has a low resistance to sunlight, and other climatic conditions, manufacturers have developed a way to boost its resistance through compounding. Generally, Nitrile Rubber (NBR) is an acceptable material for hydraulic components and pneumatics. Stainless steel is an excellent material widely used in the production of various tools and equipment. Stainless steel material contains about 10% Chromium and this gives it an excellent resistance against corrosion over other types. Thus, stainless steel is suitable to be used in different weather conditions without any damages. Stainless steel has several variations and SS302 is a type of variation. SS302 comprises about 18% and 8% of chromium and nickel elements respectively. Also, SS302 has increased carbon content. Aside from the increased resistance to corrosion, SS302 is also resistant to other substances like chemicals, acids, solvents, and many more. |

The table below shows the chemical composition of SS302:

|

3. What are the sizes available for the GS Bonded Seals?

GS Bonded is available for pipes in Metric Sizes, ANSI 36.10, and ANSI 36.19 sizes.

The table below shows the bonded seal dimensions for Metric pipe sizes according to the ISO 6162-2 standards:

The table below shows the bonded seal dimensions for Metric pipe sizes according to the ISO 6162-2 standards:

|

|

The table below shows the GS Bonded Seal dimensions for ANSI 36.10 and ANSI 36.19 pipes according to the ISO 6162-2 standards:

|

The next table shows the Bonded Seal dimensions for Metric pipe sizes according to ISO 6164 standards:

|

|

|

The table below shows the GS Bonded Seal dimensions for ANSI 36.10 and ANSI 36.19 pipes according to the ISO 6162-2 standards:

4. What are the material possibilities for the GS Bonded Seal?

GS Bonded Seal can be used with several material combinations which are shown in the table below:

This table shows the material combinations for flare flange connections:

This table shows the material combinations for flare flange connections:

Description |

Part Code |

Component Code |

Material |

Standard Assembly |

320/38X4FC |

- 320F Flange - 20/38X4FC Insert Cone - 20/38F Sleeve - 2030 Bonded Seal - OR30X1.0 O-ring |

- Electric zinced carbon steel - Electric zinced carbon steel - Electric zinced carbon steel - Electric zinced carbon steel/NBR - NBR, Shore 90 A |

Stainless Steel |

320/38X4FCSS |

- 320FSS Flange - 20/38x4FCSS Insert Cone - 20/38FCSS Sleeve - 2030SS Bonded Seal - OR30X1.0 O-ring |

- AISI 316 - AISI 316 - AISI 316 - AISI 316/NBR - NBR, Shore 90 A |

Stainless steel + electric zinced carbon steel flanges |

320/38X4FCSS/ZN |

- 320 F Flange - 20/38X4FCSS Insert Cone - 20/38FCSS Sleeve - 20/38FCSS Bonded Seal - OR30x1.0 O-ring |

- Electric zinced carbon steel - AISI 316 - AISI 316 - AISI 316/NBR - NBR, Shore 90 A |

Stainless steel + hot dip galvanized carbon steel flanges |

320/38X4FCSS/HDG |

- 320FDHG Flange - 20/38X4FCSS Insert Cone - 20/38FSS Sleeve - 2030SS Bonded Seal - OR30X1.0 O-ring |

- Hot-dip galvanized steel - AISI 316 - AISI 316 - AISI 316/NBR - NBR, Shore 90 A |

5. How is the GS Bonded Seal applied in connection component?

GS Bonded Seals are very easy to use. However, to ensure an effective and tight connection, the users must be exposed to the operation's seal mode. Please follow the steps below to use the GS Bonded Seal rightly:

STEP 1

Lubricate the GS Bonded Seal with Gleitmo 805 grease or any other seal type. Ensure the pipe ends are compatible and perfectly aligned before sealing.

STEP 2

Based on the connection end type used, either nut or thread, lubricate the bolt head compression face or flange side as the case may be.

STEP 3

Tighten the bolt or nut using the right torque value.

STEP 4

The bolts are to be tightened diagonally slowly till the right torque value is reached.

STEP 1

Lubricate the GS Bonded Seal with Gleitmo 805 grease or any other seal type. Ensure the pipe ends are compatible and perfectly aligned before sealing.

STEP 2

Based on the connection end type used, either nut or thread, lubricate the bolt head compression face or flange side as the case may be.

STEP 3

Tighten the bolt or nut using the right torque value.

STEP 4

The bolts are to be tightened diagonally slowly till the right torque value is reached.

|

Also note that:

|

gs hydro bonded seal catalogue

| GS Hydro Bonded Seal | |

| File Size: | 406 kb |

| File Type: | |