|

|

|

Material Specification |

|

Dimension Specification |

|

Outer Diameter Size |

|

Finishing |

|

Copper pipes are produced following the American Society for Testing and Materials Standards (ASTM). ASTM is an international organization founded in 1898 to set generally accepted technical standards for various products, materials, devices, and other services. Many companies trading internationally have designed their products in line with these standards set.

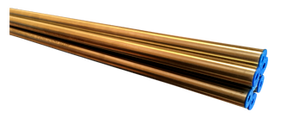

Copper pipes are available in two types; ASTM B88 and JIS H3300 C1220T. Under the classification of copper pipes, B88 pipes are referred to as Type K and Type L copper pipes. Copper pipes are popularly used worldwide due to its strength and high corrosion resistance level.

Copper pipes are available in two types; ASTM B88 and JIS H3300 C1220T. Under the classification of copper pipes, B88 pipes are referred to as Type K and Type L copper pipes. Copper pipes are popularly used worldwide due to its strength and high corrosion resistance level.

1. What is Copper Pipe made of?

The table above shows the chemical composition of Copper.

|

Copper (Cu) is a chemical element classified under Group 11 (lb) of the periodic table elements. The first use of the aspect dates back to 8000 BC when it was substituted for stone. Some elements of copper can be found in the human body and animals as well. In humans, copper acts as a catalyst for the formation of hemoglobin. Copper can be found in other natural elements like sea corals, seaweeds, etc.

Copper pipes are made from the copper element and contain 99.9% pure copper with smaller quantities of other alloys. Copper tubes are manufactured in either ASTM B88 or JIS H3300 C1220T. ASTM B88 standards are for seamless copper tubes used for fluid transfer and heat systems such as air conditioning systems (AC) and refrigerators. JIS H3300 standard is for seamless copper tubes with a round section. More so, JIS H3300 is suitable for waterworks. This can either be used for shower systems or general water connection systems in a building. |

2. What are the difference types of Copper Pipes?

During the production of copper pipes, there are six different grades available. They are Air Conditioning and Refrigeration (ACR), Medical Gas, Type K, Type L, Type M, and Type Drain, Waste, and Vent (DMV) tubes. The most common standard used in the application is type L and M tubes.

- Air Conditioning and Refrigeration (ACR) Copper Tubes: ACR copper tubes are produced in a size range between 1/4" – 4 1/8" for straight tubes and 1/8 – 1 5/8" for coils. They are made to be used in air conditioning systems.

- Medical Gas Tubes: Medical gas tubes are copper tubes used in the medical line. These copper tubes ensure equal medical gas (oxygen, nitrogen, carbon dioxide, nitrous oxide) in an environment. Before use, it is essential to ensure manufacturing oils on the surface of the material are thoroughly cleaned out to ensure patients' health is safe and to avoid combustion in the presence of oxygen.

- DWV Tubes: Streams (contaminated water) out of the building. DWV tubes also help protect water seal traps from blockage by maintaining the pressure of 1/2 to 1". When there is a case of higher water pressure, it could damage the seal traps, thereby paving the way for exposure of sewer gases into the building. Examples of DWV tubes are Cast Iron, PVC, and ABS.

- Type K Tubes: of the Types K, L, and M, Type K tubes have the thickest form of walls. These tubes are mostly used in the internal installation of water distribution channels in a building and sometimes, in the oil and gas industry, heating and anti-fire systems. Furthermore, Type K tubes serve as a foundational underground material before the construction of sidewalks and streets.

- Type L Tubes: Type L tube walls are slightly thinner than the Type K tubes. They are generally utilized for water supply systems (residential and commercial), and some pressure systems. Further, Type L tubes have a higher pressure rating than the Type M tube.

- Type M Tubes: Type M tubes have very thin walls, therefore, they are used to install residential materials. Also, it can serve as a material in low-pressure machines.

Tube Type |

Model |

Uses |

Standard Size (Straight) |

Type K |

ASTM B 88 |

|

1/4" - 4" |

Type L |

ASTM B 88 |

|

1/4" - 4" |

Type M |

ASTM B 88 |

|

1/4" - 4" |

The table above shows the above-explained copper tubes with their standard sizes.

3. What is the OD of 1" Copper Pipe?

|

By convention, the nominal bore (NB) and outer diameter are measured in inches metric size. The available diameter size ranges from 6mm to 54 mm. To measure nominal size, the outer diameter value is always 1/8 inch greater than the nominal size.

The following table shows the size value for Nominal Bore (NB) and outer diameter (OD). |

|

|

4. What is the difference between Type K, L and M Copper Pipe?

The significant difference between these three main copper pipe types is wall thickness. While Type K has the thicker walls amongst the three, others have a lower value to thickness. This wall thickness dictates the working pressure and application of each tube type.

Here’s a table showing the wall thickness, outer diameter (OD), and nominal bore (NB) for the copper tube types:

Here’s a table showing the wall thickness, outer diameter (OD), and nominal bore (NB) for the copper tube types:

Nominal Bore (NB) |

Outer Diameter (Inch) |

Outer Diameter (mm) |

Wall Thickness Type K |

Wall Thickness Type L |

Wall Thickness Type M |

1/8" |

1/4" |

6.35 |

0.035" |

0.030" |

- |

1/4" |

3/8" |

9.35 |

0.035" |

0.030" |

- |

3/8" |

1/2" |

12.70 |

0.049" |

0.035" |

0.025" |

1/2" |

5/8" |

15.88 |

0.049" |

0.040" |

0.028" |

5/8" |

3/4" |

19.05 |

0.049" |

0.042" |

0.028" |

3/4" |

7/8" |

22.23 |

0.065" |

0.045" |

0.032" |

7/8" |

1" |

25.40 |

0.065" |

0.050" |

0.035" |

1" |

1 1/8" |

28.58 |

0.065" |

0.050" |

0.035" |

1 1/4" |

1 3/8" |

34.93 |

0.065" |

0.055" |

0.042" |

1 1/2" |

1 5/8" |

41.28 |

0.072" |

0.060" |

0.049" |

2" |

2 1/8" |

53.98 |

0.083" |

0.070" |

0.058" |

2 1/2" |

2 5/8" |

66.68 |

0.095" |

0.080" |

0.065" |

3" |

3 1/8" |

79.38 |

0.109" |

0.090" |

0.072" |

3 1/2" |

3 5/8" |

92.08 |

0.120" |

0.100" |

0.083" |

4" |

4 1/8" |

104.78 |

0.134" |

0.110" |

0.095" |

5" |

5 1/8" |

130.18 |

0.160" |

0.125" |

0.109" |

6" |

6 1/8" |

155.58 |

0.192" |

0.140" |

0.122" |

With the proper use of materials, you can easily install copper tubes. Due to its formability, you can easily bend and reshape the material without fear of breakage or damage to the tube. Research has revealed that copper tubes’ bursting strength increases after bending. That is, copper tubes get stronger as they bend.

COPPER PIPES catalogue