|

|

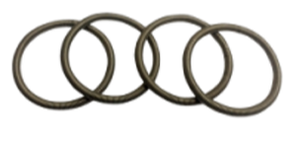

Retain rings are products of the GS-Hydro company which specializing in manufacturing non-welded technology for the connection of pipes. This connection device is designed in a way that no welding of ends is required. The retain ring creates an opportunity to connect pipes faster and easily with no threats of leakages of fluids during operation. Retain rings are mostly used in high pressure applications in various industries for different purposes. Retain rings can withstand a maximum working pressure of 690 bars and are available in sizes between 1/2” to 14”. They are made following the ISO standards ISO 6162-2 and ISO 6164. The material used in the production of retain rings is the Stainless steel SS302. |

Material Specification |

|

Design Standard |

|

Size |

|

Working Pressure |

|

1. What is a GS Retain Ring?

|

Retain rings or retaining rings are products manufactured by the GS Hydro company to serve as a connecting tool for pipes. The retain rings are classified as a non-welded technology, that is, while connecting the pipes, the welding method is not required.

More so, retain rings can operate under high pressure systems as they are designed to withstand a maximum of 690 bars. They provide an easy and fast connection means with tight joint sealing and the cost of purchase is minimal. No doubt, retain rings serve as an effective tool for high performance. |

2. What material is the Retain Ring made of?

|

Retain rings can be made from different materials such as carbon steel, Stainless steel SS316, carbon spring steel and stainless steel SS302. Other materials like beryllium, copper, phosphor bronze, etc. However, the GS Hydro retain rings are made from stainless steel SS302.

Stainless steel is an important material used in the major production of various mechanisms today. Stainless steel is an alloy made from iron and chromium and it has gained relevance due to the high strength and corrosion resistance. Asides from these elements, others are added to increase some unique qualities in the material. For example, nickel is added to stainless steel to increase its ductility, nitrogen increases the mechanical strength, aluminum serves as a resistor for oxidization, etc. Stainless steel is available in different grades such as 316, 304, 302, etc. SS302 is a stainless steel grade that is similar to the SS316. It contains chromium and nickel in 18% and 8% respectively and mostly used to produce conical compression springs and other mechanisms. |

The table below shows the chemical properties of SS302:

|

3. What are the technical features of a Retain Ring?

The retain ring can accommodate a maximum allowable pressure of 420 bar for pipes. Also, retain rings are suitable for special high pressure machines with a maximum working pressure of 690 bars.

An extensive examination of the tool has revealed the wide use of retain rings in various materials. Some of these include threaded adaptors, 3-way tees, or elbows.

An extensive examination of the tool has revealed the wide use of retain rings in various materials. Some of these include threaded adaptors, 3-way tees, or elbows.

|

The table below shows the technical data of the retain ring system:

|

Also, the table below shows the material grade to retain rings:

|

4. How is the GS Retain Ring installed?

|

The installation process of retain ring system is flexible, cost-efficient, very reliable, and essentially clean. Also, the assembling, prefabrication, and installation process is swift and carried out. During the installation preparation process, the pipe end is connected to the groove placed on the pipe. The retain ring is inserted into the groove before positioning the flanges at the pipe end.

After that, to tighten the connection, a seal is placed in the middle of the flanges. The seal for retain rings come in either Viton or NBR. Construction of the groove is flexible as it can be carried out on the installation site or workshops. |

5. What are the Retain Ring dimensions?

|

The retain rings are available in various dimensions. The table below shows the dimension of the metric pipe for retain ring system:

|

Further, the next table shows the dimensions of the drilled retain ring systems:

|

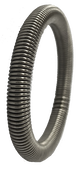

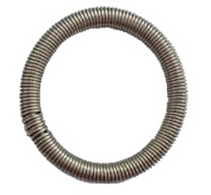

6. What is the operating principle of a Retain Ring?

|

Retain rings are used to keep the flanges and pipe connection in place. Retain rings can be in the form of a spring attached to the groove-pipe end connection or a ring made of stainless steel. The major features of the retain rings are as follows:

During the installation stage, pipe ends are compressed against the seal, and the tightening of bolts takes place. Whilst the screws and flanges grasp the shock and center force, the connection establishes a tightness assembly and stronger connection. |

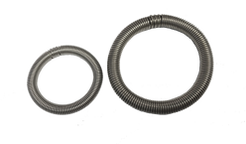

7. How do you select the right Retain Ring?

Retain rings are available in various sizes and types. There are four main types of retain ring systems which are Tapered section, circular push-on, Spiral, and Constant section.

Before selecting the retain ring for your system, you have to consider two main factors which are discussed below:

The first decision to make is selecting whether an external or internal retain ring will be used. Internal retain rings are mostly used as housing components while an external retain ring is placed in a system's shaft groove.

Retain rings are used in aerospace, oil and gas, medical, automotive, off-highway industries, and many more.

Before selecting the retain ring for your system, you have to consider two main factors which are discussed below:

The first decision to make is selecting whether an external or internal retain ring will be used. Internal retain rings are mostly used as housing components while an external retain ring is placed in a system's shaft groove.

- The next factor is selecting the type. Each retain ring type has distinct uses, however, they all work as a sealant for pipe end against connections.

- After that, the size of the retain ring should be considered. Retain rings are available in various sizes to fit into the specific purposes and industry intended. While selecting the size, the groove diameter and width should also be considered.

Retain rings are used in aerospace, oil and gas, medical, automotive, off-highway industries, and many more.

gs hydro retain ring catalogue