|

|

Tubeclo Rubber Insert Clamps are produced according to the specifications of the German Standard (DIN 3015). The DIN 3015 clamps are made in two different standards – standard series and heavy series. Tubeclo Rubber Insert Clamps come in handy when the installation of cover plates, tubes, hoses, etc. are done. Some metal products are utilized during the manufacturing of rubber insert clamps. These products are carbon steel and stainless steel. The available sizes for measurement of rubber insert clamps are in nominal bore, outside diameter, and metric sizes. Furthermore, certain features give clamps excellent vibration and noise-reducing qualities. And for versatility purposes, clamps can be produced in different sizes to fit into any given system. |

Accessories Element |

|

Body Element & Temperature Dimension |

|

Size & Series |

|

Accessories Material |

|

1. What are Tubeclo Rubber Insert Clamps?

|

These are one of the most renowned clamp types available in the market. They ensure delicate products are correctly handled and the installation process is extra-gentle. Rubber Insert Clamps, like other products on the DIN 3015 standards, are available in two series - standard series and heavy series. Furthermore, the installation process of these clamps is very swift and simple. In ensuring safety in the environment and health of workers/machines, rubber insert clamps play a vital role.

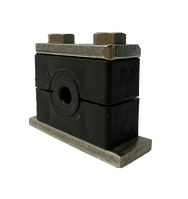

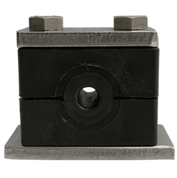

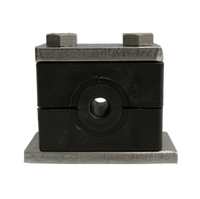

Rubber Insert clamps have a one clamp body, and one rubber inserts feature. The full assembly of a rubber insert clamp consists of two clamp halves – top and bottom. The shell body for this clamp is profile and smooth bore. For the materials used in making this clamp product, they are of 3 standard materials which are shown in the table below: |

Colour |

Material Type |

Material Code |

Special Material |

Green |

Polypropylene |

PPR |

- |

Black |

Polyamide |

PA |

- |

Black |

Elastomer Insert |

RI |

Thermoplastic Elastomer (73 Shore-A) |

A brief product summary is below:

- Great Weather Resistance: Rubber Insert Clamps have excellent weather resistance ability, and this includes being able to withstand harsh weather conditions and strong system vibration.

- Trusted, Tested and Proven materials that are versatile and can be applied in all markets and industries.

- Numerous outer diameter sizes ranging from 6mm to 32mm.

- Features components that allow extra vibration and noise reduction when the installation process is ongoing.

2. What are the uses of Tubeclo Rubber Insert Clamps?

|

These Tubeclo rubber insert clamp series are made use of in various industries and projects for diverse purposes. For example, industries in charge of paper production, construction of ships, pharmaceutical companies, metal workshops, etc all make use of rubber insert clamps during their work.

Tubeclo Rubber Insert Clamps are suitable for several purposes. They are used in industries spanning from construction, commercial, oil and gas, technology companies. They are also used in the food and chemical industries for machines used during the production process. Furthermore, they can be employed during the construction of rail lines, marine industry, automobile and hydraulic machines, energy, and technology, etc. |

3. What is Thermoplastic Elastomer (TPE)?

Thermoplastic Elastomer (TPE) is one major material used in the production of clamps. Thermoplastic elastomer (TPE), also called Thermoplastic Rubbers are materials from a group of copolymers or a mixture of polymers including thermoplastic and elastomeric properties.

The major material, Copolymers are forms of polymers produced from the combination of several monomers. The term copolymerization is used to define the process of changing monomers to copolymers. After formation, the joining of two monomers to form copolymers is called copolymers, while for three or four monomers, they are terpolymers and quaterpolymers respectively. Thermostats are other renowned materials used in several industries. However, many industries, like manufacturing companies and injection moulding factories, prefer the use of Thermoplastic elastomers (TPE) because of their easier utilization. However, the main distinguishing factor between these two materials is the form of cross-link bonding used during their formation.

There are three features a material must possess before being used to form Thermoplastic Elastomer (TPE). They are stated below:

Thermoplastic Elastomer (TPE) are classified into six classes – Styrenic block copolymers, Thermoplastic Vulcanizates, Thermoplastic polyurethanes, Thermoplastic copolyester, Thermoplastic polyolefin elastomers, and Thermoplastic polyamides.

The table on below is showing the thermoplastic elastomer features:

Thermoplastic Elastomers (TPE) are used in the production of several machines. For example, they are used in the production of automobiles. Also, they are added to roofing materials, shoe soles, adhesives, heating, ventilation and industry, medical equipment, sex toys, and many more.

The major material, Copolymers are forms of polymers produced from the combination of several monomers. The term copolymerization is used to define the process of changing monomers to copolymers. After formation, the joining of two monomers to form copolymers is called copolymers, while for three or four monomers, they are terpolymers and quaterpolymers respectively. Thermostats are other renowned materials used in several industries. However, many industries, like manufacturing companies and injection moulding factories, prefer the use of Thermoplastic elastomers (TPE) because of their easier utilization. However, the main distinguishing factor between these two materials is the form of cross-link bonding used during their formation.

There are three features a material must possess before being used to form Thermoplastic Elastomer (TPE). They are stated below:

- The material must be process-able at an elevated temperature in a melted state.

- Absence of creep or cold flow. Creep means the ability of a solid material to deform completely when put through mechanical stresses slowly.

- Should be stretchable to moderate size and return to its original state after the stress is introduced

Thermoplastic Elastomer (TPE) are classified into six classes – Styrenic block copolymers, Thermoplastic Vulcanizates, Thermoplastic polyurethanes, Thermoplastic copolyester, Thermoplastic polyolefin elastomers, and Thermoplastic polyamides.

The table on below is showing the thermoplastic elastomer features:

Thermoplastic Elastomers (TPE) are used in the production of several machines. For example, they are used in the production of automobiles. Also, they are added to roofing materials, shoe soles, adhesives, heating, ventilation and industry, medical equipment, sex toys, and many more.

|

4. What are the available sizes for Rubber Insert (RI) Clamps?

The available outer diameter sizes mostly available for rubber insert clamps measure 6mm – 172mm. When desired, the elastomer can be added for group 4 standard series clamp body shells while it is available for group 4S clamp body heavy series. Also, elastomer inserts for group 6 standard series are suitable for heavy series group 6S clamp bodies. The dimensions are given below:

|

|

Table 1.1 & 1.2: Standard Series Tubeclo Rubber Insert Clamp Size

|

|

|

|

|

|

Group |

Clamp Body Order Codes |

Rubber Body Order Codes |

Outer Diameter Tubes / Pipes / Hoses (mm) |

10S |

10150-R |

RI-150-10S |

150 |

10S |

10165-R |

RI-165-10S |

165 |

10S |

10168-R |

RI-168-10S |

168 |

10S |

10172-R |

RI-172-10S |

172 |

Table 2.1 - 2.7: Heavy Series Tubeclo Rubber Insert Clamp Size

rubber insert CLAMPS catalogue

| Stauff Rubber Insert Clamps | |

| File Size: | 71 kb |

| File Type: | |