|

|

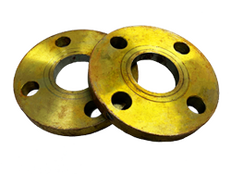

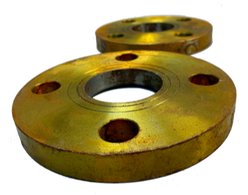

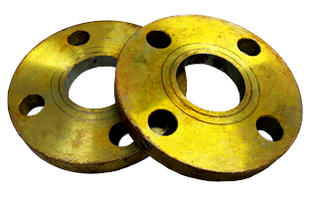

JIS10K Flange is made following the Japanese Industrial Standard (JIS) specifications. The JIS10K is a type of slip-on flange that serves as a joiner of pipes, valves through two flanges, and a gasket. This is done to prevent the leakage of fluids after the installation process is done. The JIS10K Flange follows the JIS B2220 standard and is made from Stainless Steel (SS316) and Steel (SS400). Also, the JIS10K is produced in sizes ranging from 3/8 inches to 8 inches, and it is perfect for use in all systems. The flange is very flexible and easy to use. |

Origin of Material |

|

Material Specification |

|

Working Pressure |

|

Size |

|

Connection Type |

|

Standard |

|

1. What are Flanges?

|

Flanges are tools generally used in various industries for connecting pipes, valves, tubes, and hoses to one another or a hydraulic system. They are an essential tool as they allow easy access for maintenance, cleaning, modification, and inspection of a hydraulic system. A gasket is placed in-between two flanges bolted together during connection to enable reliable sealing.

Flanges are produced in different types as they serve different purposes. For example, some flange types aren’t fit for high-pressure systems, while others can work perfectly well with high pressure and temperature. Also, there are different international companies for the standardization of the flanges. These companies have specific standards that flange-producing companies follow to ensure the product's acceptance into the market. These standards also give room for functionality and interchangeability. Furthermore, flanges are made from different materials like brass, stainless steel, and carbon steel. |

2. What are the common types of Flanges?

|

There are different types of flanges such as Welding Neck Flanges, Long Welding Neck, Slip On Flange, Threaded Flange, Socket Weld Flange, Lap Joint Flange, Blind Flange, etc. the most renowned types amongst these are:

|

|

These flanges are made per different standards which allow for differentiation of working pressure and temperature levels. The common standard types are:

These different standards have specific dimensions and measurements. Therefore, they can’t be uniformly interchanged with all flanges. Following these standards, the products have different working pressures, temperature levels, working pressure, and material grades. |

The table on above is showing these values for each standard.

|

3. What are JIS 10K Flanges?

JIS 10K Flanges are slip-on flanges used to connect pipes and valves to hydraulic systems and other components. It is made following the Japanese Industrial Standard, (JIS) JIS B2220. The flange works with a pressure of 10kg/cm², thus, the word 10K in the name.

The JIS 10K Flange is made of SS400 steel and SS316 stainless steel. These materials are quality and this gives the flange high durability and strength. The SS400 steel is a hot rolled steel made from a combination of Carbon, Silicon, Sulphur (0.050% max), Phosphorus (0.050% max), Iron, and Manganese. It is one of the widely used structural hot rolled steel.

The SS316 is one of the austenitic stainless steel made from Carbon (0.08% max), Phosphorus (0.045% max), Sulphur (0.030% max), Silicon (0.75% max), Chromium (16.00% max), Nitrogen (10.00%), Manganese (2.00% max), and Molybdenum (2.00%). The stainless steel SS316 has a very high corrosion resistance, strength and durability.

The sizes available for the JIS 10K Flange are between 3/8 inches to 8 inches. The different sizes for this flange make it suitable for usage in various machines and systems.

The JIS 10K Flange is made of SS400 steel and SS316 stainless steel. These materials are quality and this gives the flange high durability and strength. The SS400 steel is a hot rolled steel made from a combination of Carbon, Silicon, Sulphur (0.050% max), Phosphorus (0.050% max), Iron, and Manganese. It is one of the widely used structural hot rolled steel.

The SS316 is one of the austenitic stainless steel made from Carbon (0.08% max), Phosphorus (0.045% max), Sulphur (0.030% max), Silicon (0.75% max), Chromium (16.00% max), Nitrogen (10.00%), Manganese (2.00% max), and Molybdenum (2.00%). The stainless steel SS316 has a very high corrosion resistance, strength and durability.

The sizes available for the JIS 10K Flange are between 3/8 inches to 8 inches. The different sizes for this flange make it suitable for usage in various machines and systems.

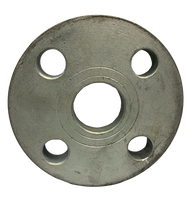

4. What is Flat Face Slip On Flanges?

|

Slip-On flanges are the most widely used pipe flange used for a pipe to borehole insertion. It is similar to the weld on flanges, however, it lacks a weld beveled end. One advantage of the flange is the allowance for adjustment of in length for the matching pipe. This space gives the individual working on the flange access to connect easily.

The slip-on flange is mostly used for low-pressure systems because a fillet weld connection is used for joining the flange to the assembly. However, a weld neck flange can be used for a high-pressure system because it has a reinforced hub, which becomes a weld beveled end at the pipe's bottom. The reinforced hub gives an increased strength for the flange to work on higher pressure. Although the weld neck flange has this advantage, it is more costly than the slip-on flange. |

5. What are the differences between a Flat Face and Raised Face Flanges?

|

Both flat face and raised face flanges are amongst the common flange faces used. They are similar, yet, with a major difference.

The flat face flange has a flat contact surface with an equal height thickness with the bolting line. A soft type gasket is placed in between the two faces before connection with a system. The flat face helps secure a flange's structure made from a susceptible material because of the torque bolts. The gasket used in flat face flanges is from non-metallic elements like EPDM or Viton. The significant difference between the flat and raised face flange is that a flat face flange has a flat area around the pipe bore, while a raised face flange lacks that. This major difference makes it impossible to join the two faces flanges together as this would lead to leakage of fluids after installation. |

6. How can JIS 10K Flanges be installed?

To connect a JIS 10K flange to another flange, follow these simple steps:

STEP 1

Carefully examine the flange faces and ensure they are thoroughly cleaned, free from dirt and other elements. Align the holes of the flange evenly after placing the gasket on the flange.

STEP 2

Ensure the holes are well aligned with the flange and gasket, then, insert bolts and washers inside the holes from the flange and gasket. Before doing this, ensure the bolts are extremely clean. After this, insert the 4 bolts with a distance of 90-degree in-between. Then, using a finger, tighten them. Make sure the alignment with the flange joint is well-positioned before the bolts are completely tightened.

STEP 3

when tightening, it is recommended that they are in four steps and the tightening torque is 20%, 50%, 75%, and 100%. This is based on the standard tightening sequence.

STEP 1

Carefully examine the flange faces and ensure they are thoroughly cleaned, free from dirt and other elements. Align the holes of the flange evenly after placing the gasket on the flange.

STEP 2

Ensure the holes are well aligned with the flange and gasket, then, insert bolts and washers inside the holes from the flange and gasket. Before doing this, ensure the bolts are extremely clean. After this, insert the 4 bolts with a distance of 90-degree in-between. Then, using a finger, tighten them. Make sure the alignment with the flange joint is well-positioned before the bolts are completely tightened.

STEP 3

when tightening, it is recommended that they are in four steps and the tightening torque is 20%, 50%, 75%, and 100%. This is based on the standard tightening sequence.

JIS flanges catalogue

| RFS JIS Fanges | |

| File Size: | 498 kb |

| File Type: | |